Concurrent Delay Analysis for Construction Claims

Concurrent delay is a vexed and complex technical and legal issue. This article addresses: the definition of concurrent delay, its treatment in various legal jurisdictions, allocation of delay responsibility when construction claims occur, factors that influence its identification and quantification, pacing vs. concurrent delay, and practical guidelines.

1. INTRODUCTION

Concurrent delay is a vexed and complex technical and legal issue for construction projects. The challenge is to equitably determine: 1) the contractor’s entitlement to a time extension as a result of an owner-responsible delay event (liability) and recovery of the contractor’s extended time-related costs (damages) that result from such delays; and 2) the owner’s recovery of its actual delay or liquidated damages when the contractor fails to complete its work by a contractual stipulated completion date as a result of a contractor-responsible delay event that is concurrent to the owner-responsible delay event.

Construction contracts often do not expressly provide direction as to the parties’ agreement when there is concurrent delay. Most simply require the contractor to provide notice and specifics when an owner-responsible delay event occurs. The owner then must determine the appropriate time extension, if any, to which the contractor is entitled. However, the owner may be reluctant to grant the contractor an extension of time if the contractor had caused its own delay during the same period. The owner also must consider its position with respect to its actual or liquidated damages as a result of the contractor-caused delay. A dispute may then occur as to whether the contractor is entitled to any extension of time if he also caused delay in the same period.

Legal jurisdictions around the world differ in contract claim and delay management in construction works, particularly in the treatment of the liability and damages aspects of concurrent delay. To help unravel the complexities of this issue, the following topics are discussed in this article:

- The Definition of Concurrent Delay;

- Treatment of Concurrent Delay in Various Legal Jurisdictions;

- Allocation of Delay Responsibility when Concurrent Delay Occurs;

- Factors that Influence the Identification and Quantification of Concurrent Delay;

- Pacing vs. Concurrent Delay; and

- Practical Guidelines for Concurrent Delay Clauses in Construction Contracts and Treatment of Claims.

2. CONCURRENT DELAY DEFINITION

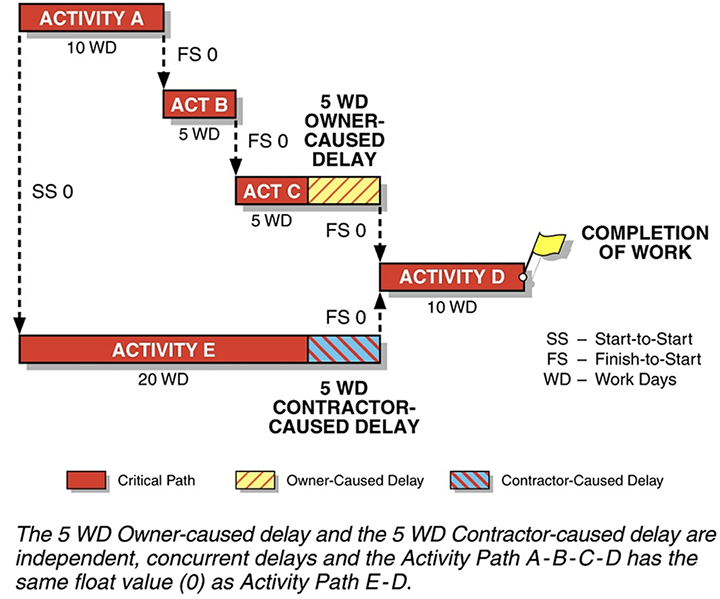

The term “concurrent delay” is commonly used to describe circumstances where different causes of delay overlap during a period of time or schedule window.1 As such, concurrent delay could occur during a window if a delay that was caused by the owner2 is on the same activity path or a parallel activity path as a delay that was caused by the contractor.3 If the owner-caused delay and contractor-caused delay affect the same activity or affect different activities on parallel activity paths which are equally critical,4 and as such the owner-caused delay and contractor-caused delay would each have delayed the completion date of the project, the delays are said to be concurrent.

For example, as shown in Figure 1, two parallel activity paths are each delayed by five work days during the same window by separate causes, one delay was caused by the owner and the other delay was caused by the contractor, and both affected activities have the same float value. The two 5‑work day delays are concurrent.

Figure 1

Illustration of Concurrent Delays

This situation is of significance when one cause of the delay is at the owner’s risk, while the other, competing cause of delay is at the contractor’s risk, and where both causes may be regarded as having caused or contributed to the delay on the project.

His Honour Judge Seymour Q.C., in Royal Brompton Hospital NHS Trust v. Frederick A Hammond (No.1), states:

However, it is, I think, necessary to be clear what one means by events operating concurrently. It does not mean, in my judgment, a situation in which, work already being delayed, let it be supposed, because [the Contractor] has had difficulty in obtaining sufficient labour, an event occurs which is a [Employer’s time risk event] and which, had [the Contractor] not been delayed, would have caused him to be delayed, but which in fact, by reason of the existing delay, made no difference. In such a situation although there is a [Employer’s time risk event], ‘the completion of the works is [not] likely to be delayed thereby beyond the completion date’. The [Employer’s time risk event] simply has no effect upon the completion date. This situation obviously needs to be distinguished from a situation in which, as it were, the works are proceeding in a regular fashion and on programme, when two things happen, either of which, had it happened on its own, would have caused delay, and one is a [Employer’s time risk event], while the other is not. In such circumstances there is a real concurrency for causes of the delay.5

3. TREATMENT OF CONCURRENT DELAY IN VARIOUS LEGAL JURISDICTIONS

In this section, the common legal practices regarding the treatment of concurrent delay is summarized in the following jurisdictions:

- U.S. law;

- English law;

- Scots law;

- Canadian law;

- Hong Kong law; and

- Australian law.

3.1 THE U.S. BENCHMARK

A primary tenet of construction contracts is that there is an implied warranty in every contract that neither party can delay or hinder the timely performance of the other party.6 In the case of concurrent delay, it is argued that both parties have delayed or hindered the timely performance of the contract.

U.S. courts and arbitration proceedings offer three approaches to the handling of concurrent delay: time but no money; apportionment; or responsibility based on a critical path delay analysis.

One author writes that the “time but no money” principle traces back to early 1900s U.S. cases when a strict rule against apportionment applied.7 In one case, the courts could not apportion “with any degree of certainty.”8 In another case, the court found that “where both parties to a contract are responsible for delay in its performance the court will not undertake to apportion the responsibility for delays.”9

The rule against apportionment was later abandoned because of the frequent use of liquidated damages clauses, the complexity of the contractual relationships, and a belief that the older rule was too harsh in its application.10 Thus, U.S. courts will apportion delay damages when evidence permits the segregation of costs resulting from each party’s causes.11 However, courts will not find for apportionment if the segregation of delay costs is impossible.12

Critical path analysis offers an alternative to apportionment in that it offers the best evidence of cause-effect analysis of time impacts, as explained in Section 4 herein.

Several cases are instructive as to U.S. law with respect to concurrent delay.

The contractor in Blinderman13 was seeking additional expenses and a time extension in respect of delays to the completion date. The contract provided that an adjustment should be made to the contract price for any increase in costs caused by suspension, delay, or interruption by the government, except where the works would have been suspended, delayed or interrupted by any other cause, including the fault or negligence of the contractor. The court found that the contractor contributed to the delays and held that:

Where both parties contribute to the delay “neither can recover damage, unless there is in the proof a clear apportionment of the delay and the expense attributable to each party.” Coath & Goss Inc. v. United States, 101 Ct.C1.702, 714-15 (1944); Commerce International v. United States, 167 Ct.C1.529, 338 F.2d.81, 90 (1964).

Generally, courts will deny recovery where the delays are “concurrent or intertwined” and the contractor has not met its burden of separating its delays from those chargeable to the Government.

The ruling in Blinderman means that neither prolongation costs nor liquidated damages are recoverable where apportionment is not possible, so an extension of time will be granted in such a case.

In Beckman Construction Company,14 the contractor sought costs associated with delay. There were concurrent delays. It was held:

Where delays for which the Government bears responsibility are concurrent with other delays due to non-compensable causes, a contractor may not recover delay costs where the non-compensable delays cannot reasonably be separated from those delays for which it is entitled to receive compensation.

It was determined that the contractor bears the burden of proving, with a reasonable degree of accuracy, the extent of delay caused by the compensable actions of the government.

In Cline Construction Company,15 also involving a claim for delay costs where there were concurrent delays, it was held:

Concurrent delay does not bar extensions of time, but it does bar monetary compensation for daily fixed overhead costs of the type claimed by Cline because such costs would be incurred on account of the concurrent delay even if the Government responsible delay had not occurred.

This ruling is consistent with Blinderman; on the facts of the case, the delay events took place at the same time (i.e., there was “true concurrent delay”) and it does not appear that the compensable and non-compensable delays could be separated. It is for this reason that an extension of time would be due. If the compensable and non-excusable delays could have been separated, Blinderman would have required that there be no extension of time for the non-excusable delay, and the owner would have been entitled to damages for the contractor’s non-excusable delay.

This finding was held to be the case in Toombs.16 The contractor sought remission of the liquidated damages deducted from monies otherwise due to him on the ground that when both parties are at fault and responsible for the delay, liquidated damages cannot be recovered from the contractor. It was held that the contractor:

…paints with too broad a brush. When it is reasonably possible to apportion the delay among the various causes, liquidated damages may be assessed notwithstanding concurrent causes attributable to both parties.

In William F. Klingensmith Inc.,17 the contractor sought a contract time extension plus impact costs where there were concurrent delays. It was held:

The general rule is that “[w]here both parties contribute to the delay, neither can recover damage[s], unless there is the proof of a clear apportionment of the delay and expense attributable to each party.” Blinderman, 695 F.2d at 559, quoting Coath & Goss. Inc. v. United States, 101 Ct.C1.702, 714-715 (1944). Courts will deny recovery where the delays are concurrent and the contractor has not established its delay apart from that attributable to the government.

In Rivera General Contracting,18 there was a claim for delay allegedly caused by the government. There were competing causes for the delay. The contract contained an adjustment of price clause similar to that in Blinderman. It was held:

Where Government caused delays are concurrent or intertwined with other delays for which the Government is not responsible, the contractor cannot recover delay damages. This principle applies equally to delays attributable to a change as to ordinary damages for delays.

Again, this is not inconsistent with Blinderman. On the facts, the delay events took place at the same time (i.e., there was “true concurrent delay”) and although the government admitted that it may have been partially responsible for some of the delays experienced, there was no evidence to demonstrate that the contractor had incurred any increased cost as a result of the government-caused delay. Therefore, there was no issue of separating the compensable from the non-compensable delay.

In Hood Plumbing,19 claims were made for delay costs and remission of liquidated damages. There were concurrent delays. It was held in relation to the claim for additional costs:

In order to recover for alleged compensable delay by the Government, a contractor must demonstrate, with a reasonable degree of accuracy, both the extent and cause of such delay. … When delays by the Government are intertwined or concurrent with delays that are not compensable, neither the Government nor the contractor may recover unless the delays can be separated or apportioned.

With regard to the remission of liquidated damages, it was held that the contractor’s delay exceeded the period of delay caused by the government and on that basis, liquidated damages could be assessed. This is not inconsistent with the principle that liquidated damages are not recoverable if delay cannot be apportioned; the assessment made in this case did amount to an apportioning of the delay.

CG Norton Co. Inc.20 was another case in which the contractor claimed delay costs plus the return of liquidated damages deducted by the government. There were several reasons, attributable to both the contractor and the government, underlying the sub-contractor’s failure to perform on time, which caused delay to completion. It was found that the reasons were “substantially chargeable” to the contractor’s conduct, whilst the government’s interference was “minimal” and a direct result of confusion fostered by the contractor’s actions. On that basis, it was concluded that the additional costs claimed did not flow from the government’s conduct.

Despite this finding on the facts, it was held that there was a concurrent delay and with regard to the assessment of liquidated damages, the court referred to the judgment in AMEC Processing Equipment Co. v. United States,21 which provided:

[W]here delays are caused by both parties to the contract the court will not attempt to apportion them but will simply hold that the provisions of the contract with reference to liquidated damages will be annulled.

It was held:

Liquidated damages may not be assessed for periods encompassed by concurrent delays…

This decision appears to be in conflict with Toombs. However, the decision can be distinguished on the ground that it involved a single delay event to which both the contractor and the owner had contributed, as compared with concurrent delay involving two distinct delay events, each with a separate cause. Therefore, it did not really involve a “concurrent delay” scenario. Further, the delay experienced could not in any event be apportioned and so liquidated damages were impossible to assess.

In Calumet Construction Corporation v. Metropolitan Sanitary District of Greater Chicago,22 the contractor, Calumet, brought a suit for breach of contract and return of liquidated damages. It was agreed that there had been “mutual delay”. Calumet argued that because the owner, MSD, had contributed to the delays in the work and fault could not be apportioned under the liquidated damages clause of the contract, the entire amount of liquidated damages should be returned to Calumet. MSD argued that, pursuant to the terms of the contract, it had granted day-to-day extensions to Calumet for the delays it had caused, that there was a question of fact concerning who was responsible for the additional alleged delays, and that, contrary to Calumet’s contention, the liquidated damages clause could be apportioned on the basis of fault under the terms of the contract and was, thus, enforceable. It was held:

Specifically, the issue presented on appeal here concerns whether courts can apportion fault for mutual delay between two contracting parties pursuant to a liquidated damages clause. This issue has never been squarely addressed by Illinois courts, and courts of other jurisdictions presented with this issue generally follow either the so-called more “modern rule” of apportionment [FN2] concerning liquidated damages, or the “older view” which prohibits apportionment under such provisions. (See Sobel, Owner Delay Damages Chargeable to Performance Bond Surety (1984), 21 Cal.W.L.Rev.128,133-34). The older view is that, in construction contracts, if the owner contributed to the delay at all, the owner could not recover any liquidated damages, and the liquidated damages clause would be abrogated in those circumstances. (See General Insurance Co. of America v. Commerce Hyatt House (1970), 5 Cal.App3d 460,85 Cal.Rptr.317; State v. Jack B. Parson Construction (1969), 93 Idaho 118, 456 P.2d 762; L.A. Reynolds Co. v. State Highway Commission (1967), 271 N.C. 40, 155 S.E.2d 473; Lee Turzillo Contracting Co. v. Frank Messer & Sons, Inc. (1969), 23 Ohio App.2d 179, 261 N.E.2d 675.) The older rule of non-apportionment, however, is now being abandoned by a growing number of courts in favour of the more modern rule of apportionment because of the increasing popularity of liquidated damages clauses, in part, due to the increasing complexity of contractual relationships, and, in part due to the fact that the older rule is too harsh in its application. (See E.C. Ernst, Inc. v. Manhattan Construction Co. (5th Cir. 1977), 551 F.2d 1026, cert denied sub nom, Providence Hospital v. Manhattan Construction Co. (1978), 434 U.S., 1067, 98 S.Ct.1246, 55 L.Ed.2d 769.) This trend in favour of apportionment is similar in nature to the trend in the courts to apply a comparative negligence standard in tort cases, i.e., recovery is based on apportionment of the responsibility of the parties rather than on the disqualification of a party merely because he was guilty of some fault. (See Sobel, 21 Cal.W.L.Rev. 128, 133). Under the modern rule concerning liquidated damages, courts (including the Supreme Court of the United States, as noted) will determine the amount of fault attributable to each party, and, as long as the owner has not delayed in bad faith, they then award liquidated damages according to that finding. Robinson v. United States (1923), 261 U.S. 486, 43 S.Ct. 420, 67 L.Ed 760; E.C. Ernst, Inc. v. Manhattan Construction Co. (5th Cir.1977), 551 F.2d 1026; U.S. ex rel. Thorleif Larsen & Son, Inc. v. B.R. Abbot Construction Co. (7th Cir.1972), 466 F.2d 712; Aetna Casualty & Surety Co. v. Butte-Meade Sanitary Water District (D.S.D.1980), 500 F.Supp.193; Nomellini Construction v. State of California (1971), 19 Cal.App.3d 240, 96 Cal.Rptr.682.

FN2. Although we refer to the rule of apportionment as the “modern rule”, we note that in 1923, the United States Supreme Court applied the rule of apportionment under a liquidated damages clause. (Robinson v. United States (1923), 261 U.S. 486, 43 S.Ct.420,67 L.Ed. 760.) Other courts and commentors, nevertheless, refer to the rule as the “modern rule” because it is only recently that more jurisdictions have begun to apply the rule.

…

We agree with the MSD that the proper rule to be applied is the modern rule of apportionment. …

…

Further, we find no merit in Calumet’s contention that it is too difficult to apportion fault under a liquidated damages clause. (See Robinson v. United States (1923), 261 U.S. 486, 43 S.Ct. 420, 67 L.Ed. 760, where the Supreme Court found no difficulty in apportioning fault under a liquidated damages provision.) A court would have no more difficulty ascertaining proportional fault under a liquidated damages clause than it would in a case of comparative negligence involving actual damages. Hence, we conclude that the older rule of non-apportionment is too harsh, and not in accord with current policy in cases concerning a valid liquidated damages clause. We, therefore, hold that the modern rule of apportionment should be applied here.

However, while we adopt the modern rule of apportionment, we find that just as the rule should not apply in those situations where the owner has acted in bad faith, the rule also should not apply in situations where the owner … has substantially contributed to the delay, i.e., where the owner has made it practically impossible for the contractor to complete the work as scheduled. This limitation on the rule is necessary because if the evidence shows that the owner substantially contributed to the delay to such an extent, then its delay effectively alter the terms of the contract, and in such a case, the owner’s act must be held to have rendered the clause providing that “time is of the essence” to be void, and of no effect.

… the parties must, therefore, present evidence to show whether there was mutual delay, and to whom the delay was attributable. If the evidence shows that that the MSD substantially contributed to the delay so as to render the provision of the contract providing that time is of the essence void, the court must then abrogate the liquidated damages clause, and the parties may only then seek any actual damages that they are able to prove. If, however, the evidence does not show that the MSD substantially contributed to the delay, the court may apportion fault under the clause and award liquidated damages accordingly.

This case did not refer to “concurrent delay,” nor did it address the other authorities on the subject. However, it confirmed that where there is concurrent delay in the wider sense, the owner does not automatically lose the right to liquidated damages. In the case of such delay, the court should seek to apportion the same based on the evidence presented to it. Although the court will not apportion the delay when the owner has “substantially contributed” to it (akin to “prevention”), and liquidated damages will not be recoverable in that case, general damages may still be sought.

In Volpe-Head (Joint Venture),23 the court reiterated the rule set out in Commerce International v. United States,24 that “there can be no recovery where the (owner’s) delay is concurrent or intertwined with other delays.” The contractor’s claim for delay damages was denied because it would not have been able to carry out the works anyway because of its own default, notwithstanding the owner’s failure to give access to the worksite.

In Wilner Construction Co.,25 the contractor was seeking delay damages where there were concurrent delays. It was held:

Determining responsibility for delay is essential. A contractor typically may not recover if government-caused delays concurrent with additional delay not caused by the Government such as weather or contractor delays.…This rule is less rigid than it may appear.

The court then confirmed the general rule as stated in Klingensmith above.

In B.D. Collins Construction Company,26 the contractor was seeking compensation for delay in respect of which an extension of time had already been granted. There were excusable and non-excusable delays that were held to be inextricably intertwined with government caused delays. It was held that because these delays were inextricably intertwined, the whole period of concurrent delay became non-compensable.

JBL Construction Company Inc.27 was another case involving concurrent delay where the contractor sought compensation for delay. It was held:

When the delays result from a combination of causes, and both parties are at fault to such extent that it is not possible to determine the degree of guilt of each, the Government loses its right to assess liquidated damages and the contractor loses the right to collect delay costs.

Such was found to be the case there.

In Appeal of Coffey Construction Company Inc. VABCA No. 3661 (11 February 1993),28 the general rule stated in Klingensmith Inc. v. United States 731 F.2d 805 (referred to in Wilner above) was adopted. It was held:

Where the delay is prompted by inextricably intertwined concurrent Government and contractor causes, the delay is not compensable nor are liquidated damages assessable.

In Smith v. The United States,29 the government terminated a supply contract for failure to deliver in accordance with the same. The contractor complained that its failure to perform was the result of delay and disruption caused by the government. However, the court found that the contractor had made no attempt to recognize and apportion the amount of delay, for which it was responsible. It was held:

A contractor may not collect damages from the government due to delay where that contractor was itself in a state of concurrent delay. “Generally, courts will deny recovery where the delays are ‘concurrent or intertwined’ …” [FN22] Even where both parties are responsible for delay, a contractor may not recover unless it is able to apportion the delay and expense attributable to each party. [FN23] The burden of apportioning delay falls on the plaintiff. “Courts will deny recovery where delays are concurrent and the contractor has not established its delay apart from that attributable to the government.” [FN24] Plaintiff’s delay claims require analysis as to the validity of plaintiff’s cited examples of government caused delay, and analysis of plaintiff’s state of readiness at those times.

FN22. Blinderman Constr. Co v. United States, 695 F.2d 552, 559 (Fed.Cir.1982).

FN23. Coath & Goss, Inc. v. United States, Ct.Cl. 702, 714-15, 1944 WL 3694 (1944).

FN24. William F. Klingensmith, Inc. v. United States, 731 F.2d 805, 809 (Fed.Cir.1984).

…Accordingly, (the contractor’s) claim fails because (it) cannot clearly apportion the alleged delay caused by the government from its own delay.

3.2 ENGLISH LAW

Under English law, the “Prevention Principle” applies to the determination of liability and damages resulting from concurrent delay. Unless contractually provided otherwise, which is rare, “the essence of the prevention principle is that the promisee cannot insist upon the performance of an obligation which he has prevented the promisor from performing.”30 The but-for test may also apply, wherein the owner argues that the owner-responsible event relied upon by the contractor in fact caused no delay because the contractor had caused delay to the completion of the works. The defense is that the contractor cannot prove that it would have completed on time “but-for” the owner’s delay.

The Dominant Cause approach to resolving the concurrent delay issue suggests that when concurrent delay occurs, one an owner risk event and the other a contractor risk event, only one of the delays is the dominant cause for the delay to the project and prevails over the other cause of delay.31 Difficulties with this approach include 1) the triers of fact must make a decision as to which of the delays is dominant, which may be inherently difficult; 2) requires the relaxation of the but-for test; and 3) may conflict with the prevention principle.

The most significant English case regarding concurrent delay was Henry Boot Construction v. Malmaison in 1999.32 The court found that:

If there are two concurrent causes of delay, one of which is a Relevant Event [an employer risk event], and the other is not, then the contractor is entitled to an extension of time for the period of delay caused by the Relevant Event notwithstanding the concurrent effect of the other event.

The finding became known as the “Malmaison” approach. The Malmaison approach took no account of concurrent contractor delays and was harsh on owners. Editors of Keating describe Malmaison as “the now accepted approach to resolving issues of true concurrency in the context of extension of time claims where one of the competing causes of delay cannot be said to be the dominant cause.”33 The approach supports the proposition that the trier of fact, when determining the delaying effect of an owner risk event is not permitted to consider the effects of other events.

The Malmaison approach is adopted by the Society of Construction Law:

Where Contractor Delay to Completion occurs concurrently with Employer [Owner] Delay to Completion, the Contractor’s concurrent delay should not reduce any EOT [Extension of Time] due;34

3.3 SCOTS LAW

In a departure from the Malmaison approach, the position under Scots law stems from the City Inn litigation.35 The court apportioned delay between the relevant (owner risk) events and the contractor-caused delays considering their relative importance and degree of responsibility for each delay. It granted the contractor, Shepherd, a nine-week extension of time out of a claim of 11 weeks delay. Thus, City Inn may allow apportionment based on the contractual requirement to be “fair and reasonable.”

English courts are not bound by Scots law, and continue their preference for the Malmaison approach.

3.4 CANADIAN LAW

According to one author, “Canadian courts do not recognize an all or nothing approach,” and unlike U.S. courts, “the Canadian system does not place a high evidentiary burden on a claimant as a prerequisite to apportionment.”36 Thus, Canadian courts tend to favor apportionment and “do the best they can.”

3.5 HONG KONG LAW

Hong Kong courts have typically applied the Malmaison approach to issues of concurrent delay, although more recent decisions suggest a movement towards the apportionment approach.37

3.6 AUSTRALIAN LAW

Australian standard forms of contract have attempted to provide a solution to the concurrent delay issue without success because not all forms are consistent or clear. In fact, one contract provides no time extension when the contractor is responsible for concurrent delay.38 Other forms, such as clause 34.4 in AS 4000-1997 and AS 4902-2000, provide for apportionment in the event of concurrent delays. Absent a contractual provision, it has been suggested that the “position under Australian law would reflect the approach of English law by reverting to the common law.”39 However, one author suggests that apportioning delays would be preferable.40

3.7 OTHER SOURCES OF GUIDANCE REGARDING THE COST IMPLICATIONS OF CONCURRENT DELAY

Other industry commentators have suggested guidelines regarding the assessment of cost responsibility in situations where concurrent delay occurs:

In cases where it is not possible to apportion the loss, because for example, the costs flowing from the compensable Owner-caused delay event and the non-compensable Contractor-caused event are inseparable, the loss should lie where it falls. In such cases, the Owner is precluded from claiming its delay damages as it is concurrently responsible for the delay. Similarly, the Contractor is unable to claim for the cost consequences of the delay, as it would have been exposed to these costs in any event as a result of its own delays.41

Where they have had the opportunity to rule on the issue, the courts and tribunals in the UK, Hong Kong and the US have tended to adopt a similar approach, in regard to extensions of time: in situations of true concurrency, the developer’s time risk event carries the day and [the Contractor] should be granted an extension of time for its effect on completion. As [the Owner] is conversely denied liquidated damages from [the Contractor], this approach can be regarded as the default position of leaving the losses where they fall. The prevention principle, the doctrine of penalties, burden of proof considerations and the contractual status of construction programmes have all been cited in justification of such an approach.42

In relation to concurrent delay the protocol suggests that the Contractor should be entitled to an extension of time but only to any costs caused by the Employer’s delay over and above those caused by the Contractor’s concurrent delay.43

…as for money, it even explains that the awarding of extensions of time for concurrent delay does not automatically run up a prolongation claim.44

3.8 CONCLUSION

Thus, the international construction industry has primarily adopted the principle that, for periods of concurrent delay, the contractor would not have entitlement to recover its delay costs and, likewise, the owner would not have entitlement to recover its liquidated damages or actual delay costs. However, some affinity for apportionment has been adopted in certain jurisdictions. As will be demonstrated in the following sections of the article, the use of CPM scheduling provides an analytical tool to fairly apportion delay responsibility and allocate delay damages when concurrent delay exists.

4. ALLOCATION OF DELAY RESPONSIBILITY WHEN CONCURRENT DELAY OCCURS

In situations of concurrent delay, the construction contracts between the parties must first be examined to determine whether they provide an answer to how the allocation of liability for any concurrent delay should be considered without sophisticated analysis.

The contract between the parties may provide no direct guidance as to the treatment of concurrent delay. However, certain contracts may be more explicit, stating that neither party is to receive compensation when delays are concurrent. Some contracts go further and state that when concurrent delay occurs, not only is no delay compensation available to either party, but the contractor is not entitled to a time extension. The latter would be an unusual provision for which the contractor may be accepting significant risk if liquidated damages also apply in the event of delay to the project. Legal opinion should be sought in this case.

Notwithstanding the aforementioned problem, if no contractual provision states otherwise, the most commonly applied principle applied in the international construction industry is that, if the owner-caused and contractor-caused delays are concurrent and of equal duration, and if they equally affected the critical path to project completion or another milestone date, the contractor would not be entitled to compensable delay damages and the owner would not be entitled to its actual delay or liquidated damages.

In such cases, there is usually no requirement that concurrent delays be equally critical. In addition, it also follows that non-critical delays can be used to offset compensable delay on a day‑for-day basis after the calculation of relative float is determined for the critical and near critical paths. This practice is part of the recommended practice set forth by AACE International, which states:

Concurrency analyses should always be consistent with the contract’s definition of criticality. While it is beyond the scope of this document to catalogue the variations in contractual specifications, one relatively common definition is worth mentioning. Namely, some contracts include in the definition of concurrent delay that it cause a critical path delay. The requirement that the concurrent delay be critical, in effect, excludes other delay events with float values greater than the critical path from being evaluated for offsets against compensable delays. This view comports with the Literal Theory. It can be argued that absent such contract definition, non-critical delays can be used to offset compensable delay on a day-for-day basis after the expenditure of relative float against the critical path. This view comports with the Functional Theory.45

This practice is commonly applied in the evaluation of concurrent delay.

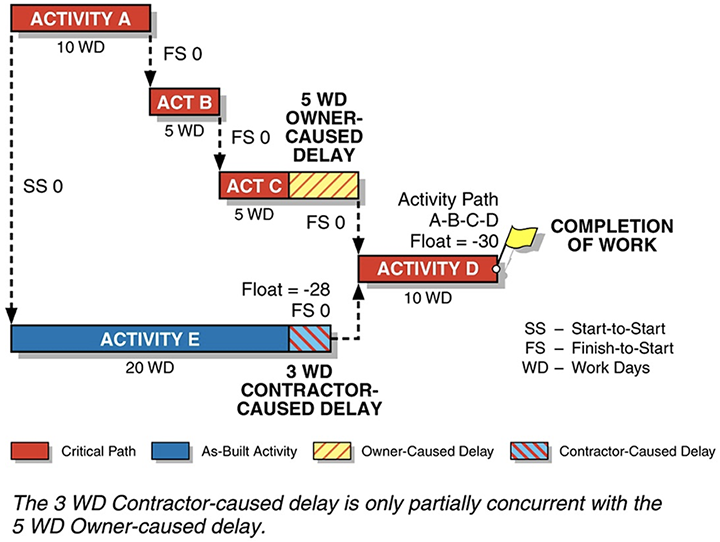

Thus, if one delay occurs on an activity path, and a parallel activity path experiences another delay, but the two activity paths have different float values, then the number of concurrent delay days is calculated after the float difference between the two activities is considered.

This concept is shown conceptually in Figure 2 on the next page. In this example, the owner caused 5 work days of delay to an activity during a window, and the As-Built Calculation Schedule46 shows that activity to have minus 30 work days of float (negative float equals 30 work days). During the same window, the documentation shows that the contractor caused 3 work days of delay to a different activity, and the As-Built Calculation Schedule shows that activity has minus 28 work days of float (negative float equals 28 work days). Because of the difference in float values, 2 work days of the overall 5 work days of delay must first be subtracted from the overall delay because of the 2 work day difference in float value for the two parallel activity paths that are affected by two different delays. The remaining 3 work days of delay are concurrent, and the 2 work days of delay to Activity C is a non-concurrent delay. The responsibility for the 2 work day delay is attributed to the owner, and the contractor receives 2 work days of compensable delay. The contractor receives a 5-work day time extension, but no compensation for the 3 work days of concurrent delay.

Figure 2

Concurrent Delays Affecting Activities with Different Float Values

Several respected international construction industry sources have provided guidance regarding the allocation of liability when concurrent delay occurs. Guidance from the following two of these sources is summarized in the paragraphs that follow:

- AACE International, and

- The Society of Construction Law (SCL).

4.1 AACE INTERNATIONAL’S RECOMMENDED PRACTICE NO. 29R-03 FORENSIC SCHEDULE ANALYSIS

AACE International’s Recommended Practice for forensic schedule delay analysis states the following:

In the absence of any contractual language or other agreements, the conventional rule governing compensability is that the claimant must first account for concurrent delays (see subsection 4.2) in quantifying the delay duration to which compensation applies. That is, the contractor is barred from recovering delay damages to the extent that concurrent contractor-caused delays offset owner caused delays, and the owner is barred from recovery liquidated or actual delay damages to the extent that concurrent owner-caused delays offset contractor-caused delays.

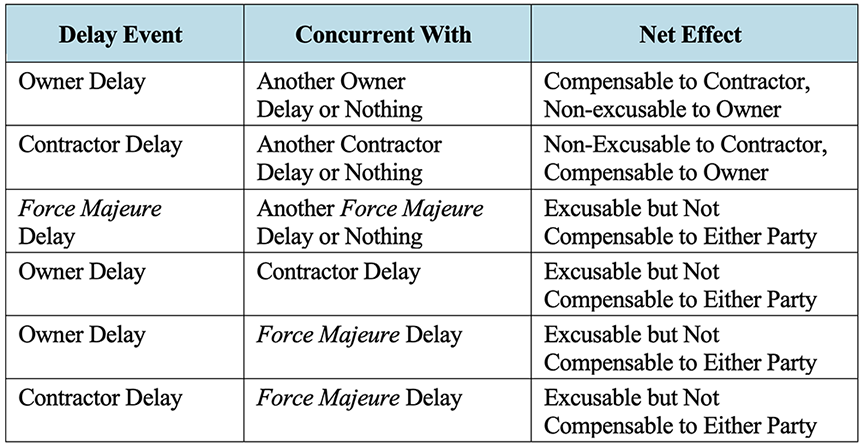

The evaluation proceeds in two distinct steps. First, the liability for each delay event is individually analyzed.47 The classification is made primarily according to the responsibility for the cause of the delay, but may also consider the contractual risk allocation of the delay event regardless of the party who caused such delay. The second step consists of evaluating whether each delay event is concurrent with other types of delays to arrive at the final conclusion of compensability, excusability or non-excusability.48

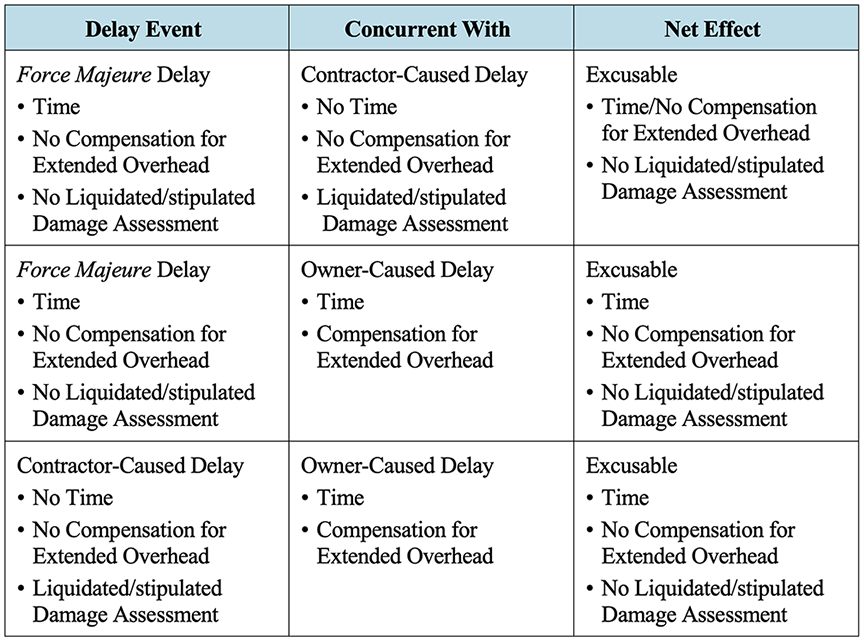

The various permutations of concurrent delay are summarized by AACE International in Table 1:49

Table 1

Concurrent Delay Scenarios and Net Effect

AACE International also sets forth its Recommended Practice with respect to concurrent combinations of delay, as shown in Table 2:50

Table 2

Concurrent Delay Combinations and Net Effect

AACE International also states the following with respect to compensability when concurrent delay occurs:

Thus entitlement to compensability, whether it applies to the contractor or the owner, requires that the party seeking compensation shows a lack of concurrency if concurrency is alleged by the other party. But for entitlement to excusability without compensation, whether it applies to the contractor or the owner, it only requires that the party seeking excusability show that a delay by the other party impacted the critical path.

Based on this symmetry, contractor entitlement to a time extension does not automatically entitle the contractor to delay compensation. The contractor would first have to show that an owner delay impacted the critical path, and then if the owner defends alleging concurrent delay, the contractor would have to show the absence of concurrent delays caused by a contractor delay or a force majeure delay in order to be entitled to compensation.

A contractor delay concurrent with many owner delays would negate the contractor’s entitlement to delay compensation. Similarly, one owner delay concurrent with many contractor delays would negate the owner’s entitlement to delay compensation, including liquidated/stipulated damages. While in such extreme cases the rule seems draconian, it is a symmetrical rule that applies to both the owner and the contractor and hence ultimately equitable.51

Thus, AACE International states that the owner is not entitled to delay damages for the period of compensable delay.

4.2 THE SOCIETY OF CONSTRUCTION LAW DELAY AND DISRUPTION PROTOCOL

The Society of Construction Law (the SCL) published a protocol on delay and disruption, dated October 2002 (the Protocol).52 The Protocol aims to provide useful guidance on issues that arise on construction contracts in order to provide a means by which the parties can resolve issues and avoid disputes. It is not intended, nor does it purport, to take precedence over the express terms of a contract or be a statement of law.53

In relation to concurrent delay, the Protocol includes the following guidance:

- True concurrent delay is the occurrence of two or more delay events at the same time, one an Employer Risk Event, the other a Contractor Risk Event, and the effects of which are felt at the same time. True concurrent delay will be a rare occurrence. A time when it can occur is at the commencement date (where for example, the Employer fails to give access to the site, but the Contractor has no resources mobilised to carry out any work), but it can arise at any time.54

- Where Contractor Delay to Completion occurs concurrently with Employer [Owner] Delay to Completion, the Contractor’s concurrent delay should not reduce any EOT [Extension of Time] due;55

- Where Employer Risk Events and Contractor Risk Events occur sequentially but have concurrent effects, here again the Contractor Delay should not reduce the amount of EOT due to the Contractor as a result of the Employer [Owner]Delay;56

- If the Contractor incurs additional costs that are caused both by Employer[Owner]Delay and Contractor Delay, then the Contractor should only recover compensation if it is able to separate the additional costs caused by the Employer [Owner] Delay from those caused by the Contractor Delay;57 and

- If it would have incurred the additional costs in any event as a result of Contractor Delays, the Contractor will not be entitled to recover those additional costs.58

Thus, the SCL Protocol is consistent with AACE International, and provides that in the event of concurrent delay, the contractor is entitled to a time extension for the amount of delay caused by the owner despite the contractor-caused concurrent delay, but the contractor is not entitled to delay costs for the period of concurrent delay. This approach is consistent with a legal system which applies a strict rule of causation to damages claims generally, and has been applied, for example, in the U.S. and England.59

5. FACTORS THAT INFLUENCE THE IDENTIFICATION AND QUANTIFICATION OF CONCURRENT DELAY

Factors that influence the identification and quantification of concurrent construction delay claims include the following:

- Whether concurrency is determined literally or functionally;

- Whether concurrency is determined on the cause or the effect of delay;

- The frequency, duration and placement of the analysis interval;

- The order of delay insertion or extraction in a stepped implementation; and

- Whether the analysis is done using full hindsight or based on knowledge-at-the-time.

These factors are discussed in the following sections.

5.1 FUNCTIONAL OR LITERAL CONCURRENCY

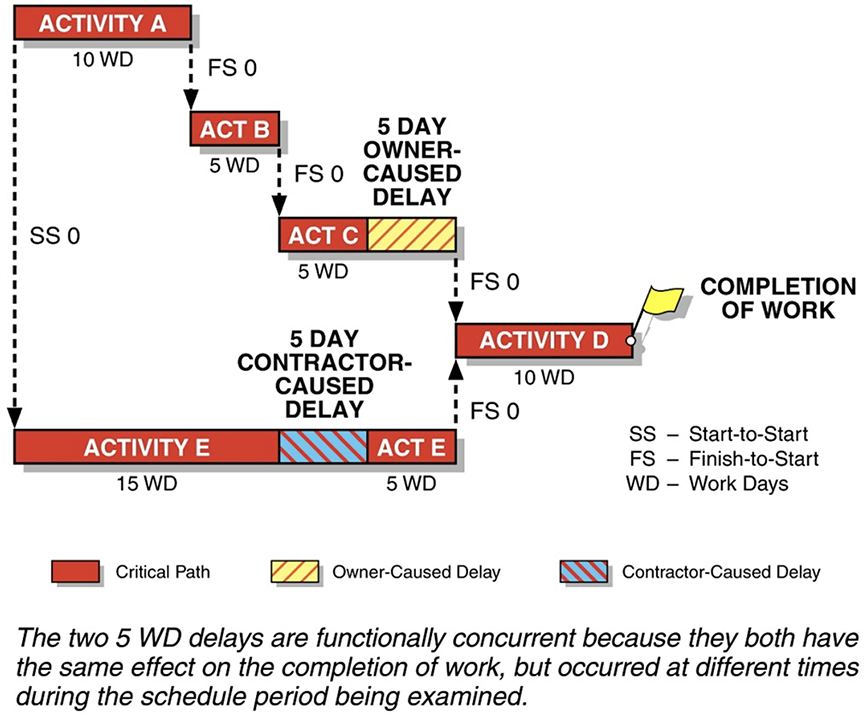

Functional concurrency occurs when the separate network paths, on which the delays reside, concurrently impact the Completion of Work date, as shown in Figure 3.

Figure 3

Illustration of Functional Concurrent Delays

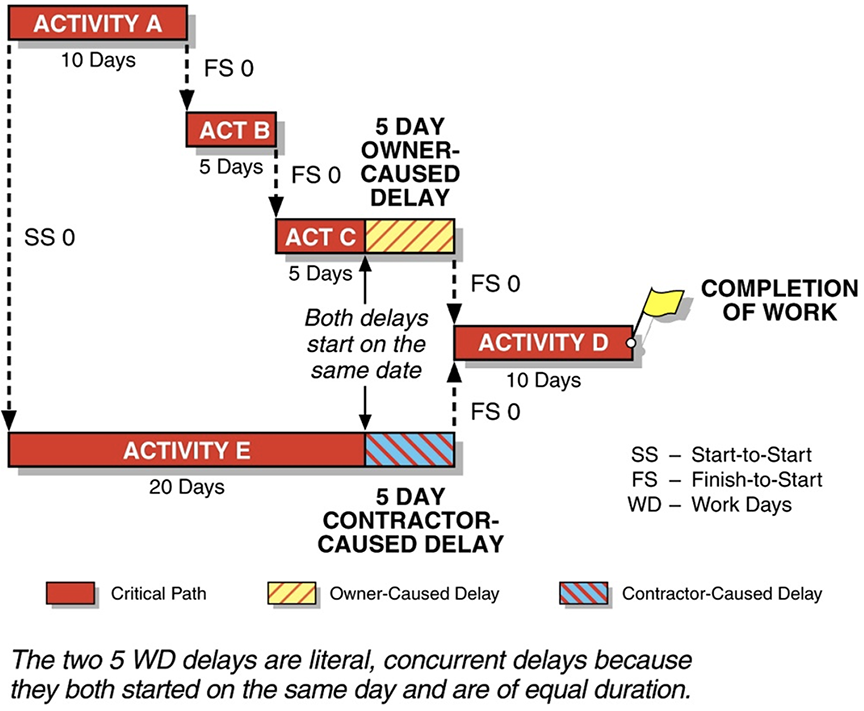

Literal concurrency occurs when two or more delay-causing events occur at the same time, as shown in Figure 4. Literal concurrency is an unachievable definition because time is infinitely divisible.

Figure 4

Illustration of Literal Concurrent Delays

The functional theory is “closely attuned to delay methodologies that use modeled CPM schedules as their basis and utilize some form of time period analysis. Since these analyses measure delay at the end of time periods [typically the status updates] it makes sense to measure concurrency under this methodology at the same points, rather than trying to develop a separate concurrency analysis. Accordingly, the functional application of concurrent delay theory does not necessarily require the delay events to occur at the same time. In addition, the functional theory allows that CPM schedules, even if properly maintained, are not perfect, and near critical delays may in fact be concurrent.”60

5.2 CAUSE OF DELAY VS. EFFECT OF DELAY

There is a distinction between concurrent causes of delay and the concurrency of the effects of delay. Likewise, there is a distinction between sequential events which cause concurrent delay and coincident events which cause concurrent delay.

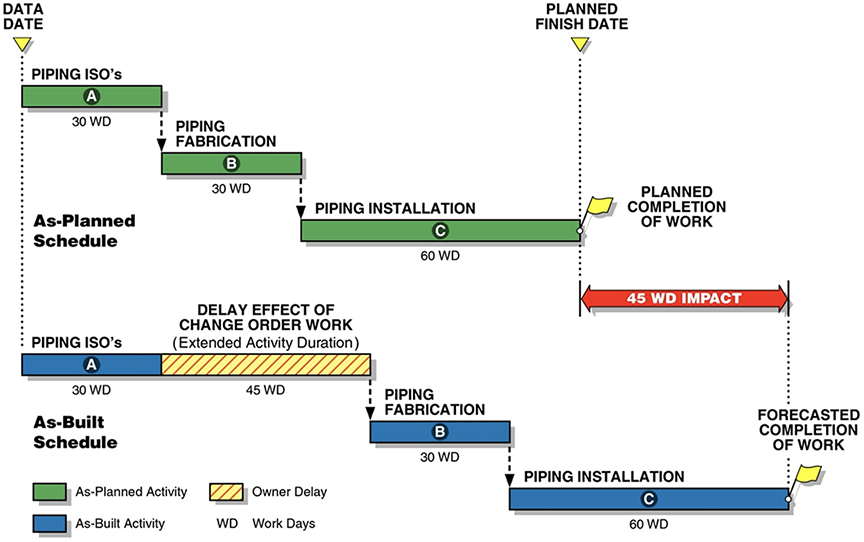

The delay-cause approach is based on the identification of delay as independent of the planned duration for an activity, and is driven by the nature of the event. The delay-cause analysis is portrayed in Figure 5.

Figure 5

Illustration of Delay-Cause Analysis

In this example, Activity A, Piping Isometrics, was planned to take 30 work days. A change order, however, was issued 15 work days after the start of Piping Isometrics and required 45 work days of additional Piping Isometric work. The cause of the delay was the change order. By adding the 45‑work day delay at the time that the change order was identified, the resultant schedule Completion of Work date can be forecasted.

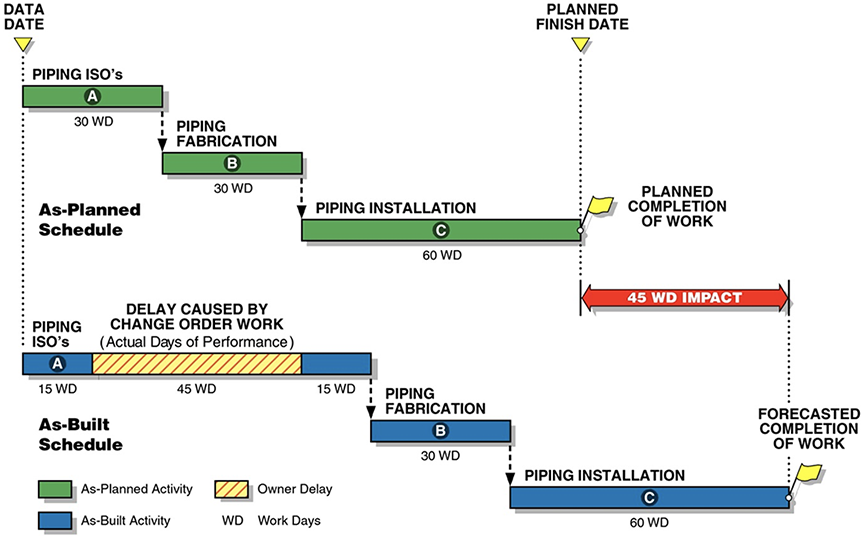

The delay-effect approach is premised on the basis that there is no ‘delay’ until the planned duration of an activity that has been affected by a delay has been exhausted. The delay-effect analysis is portrayed in Figure 6.

Figure 6

Illustration of Delay-Effect Analysis

Again, Activity A, Piping Isometrics, was planned to take 30 work days. The effect of the change order, as measured when the change order work was actually completed, was to extend the completion of Piping Isometrics by 45 work days for additional Piping Isometric work. A further effect of the delay was to delay the planned finish date for Activity C, Piping Installation, by 45 work days.

If there are no discrete events that cause a schedule activity to exceed its planned duration, the delay analysis would have to fall back to the delay-effect method of identifying the delay. Conversely, in cases where the delay was a result of a series of discrete events, the delay-effect method of chronological placement of delay would often be at odds with contemporaneous documentation of such discrete events.

A schedule analysis that incorporates both the “cause of delay” and “effect of delay” may have merit. The “cause” approach looks at discretely identifiable delay causes or impacts based on the contemporaneous project records. Discrete causes of delay may include drawing delivery delays, Change Order impacts, etc. The “effect of delay” is quantified by the delay variances in Duration Variance and Lag Variance Tables61 that are prepared at the start and finish of each schedule window. This approach aligns the delay causes with the effects, based on the available documentation, to understand both the cause and the effect of delay. This approach is consistent with AACE International’s Recommended Practice, which states:

There are two solutions to reconcile this potential dichotomy between the static and dynamic methods. One solution is to use the cause theory where discrete delay events are identifiable and to use the effect theory where there are no identifiable discrete events that led to the delay. But note that in many cases the identification of discrete causes is a function of diligence in factual research, which is in turn dictated by time and budget allowed for the analysis. The second solution is to review the delay on an activity basis and not to review the events on a daily basis within the event. This solution comports with the reality that delays that occur at the outset of an activity may be made up during the performance of that activity.62

The distinction between delay-cause and delay-effect is more important when using the literal theory of concurrency. If delays are concurrent only when they occur on the exact same day, then it is important to establish that the cause (not effect) of both concurrent delays occurred on the same day. If the functional theory of concurrency is used, where delays are concurrent if they both have the same effect of delay to the completion date, it is not necessary to establish that two concurrent delays were both caused on the same day, or to carry it further, the same hour, the same minute, etc.

5.3 FREQUENCY, DURATION AND PLACEMENT OF ANALYSIS INTERVALS

Analysis intervals are the individual time periods, or windows, used in analyzing the schedule. The frequency, duration, and placement of the analysis intervals are the most significant technical factors that influence the determination of concurrency.63

Frequency refers to the number of windows during which the overall project is divided for analysis.

Duration refers to the number of days that comprise the window. Schedule delay analysis are often based on each window having a duration of approximately one-month, which is consistent with industry practice of updating the schedule monthly and eliminates any subjectivity caused by irregular window cut-off dates.

AACE International discusses the reliability of the result based on the chronological placement of the boundaries of the windows, or the cut-off dates:

There are two main ways that the analysis intervals are placed. The first method is to adopt the update periods used during the project by using the data dates of the updates, which are usually monthly or some other regular periods dictated by reporting or payment requirements. The other is the event-based method in which the cut-off dates are determined by key project events such as the attainment of a project milestone, occurrence of a major delay event, change in the project critical path based on progress (or lack thereof), or a major revision of the schedule. Event-based cut-off dates may not necessarily coincide with any update period.

The most distinguishing feature of the event-based placement of cut-off dates is that there is significant independent judgment exercised by the forensic analyst in choosing that time period. Because the cut-off date is equivalent to the data date used for CPM calculation, it heavily influences the determination of criticality and float, and hence the identification and quantification of concurrent delays. Also, as stated above, the placement of cut-off date plays a major role in how the canceling effect operates.64

According to AACE International, the windows analysis is influenced by the functional or literal theory of concurrency:

Concurrency is evaluated discretely for each analysis interval. That is, at the end of each period, accounting of concurrency is closed, and a new one opened for the next period. This is especially significant when analysis proceeds under the functional theory of concurrency in cases where two functionally concurrent delay events, one owner delay and the other a contractor delay, are separated into separate periods. If those delay events were contained in one period, they would be accounted together and offset each other. When they are separated, they would each become compensable to the owner and the contractor respectively. The analyst is recommended to analyze multiple-period events in both separate periods and combined periods to achieve the most accurate results.

However, the distinction between the functional and the literal theories does not disappear automatically with the use of multiple analysis intervals. Two delay events separated by time within one analysis interval will still be treated differently depending on which theory is used. The distinction becomes virtually irrelevant only when the duration of the analysis interval is reduced to a single day.

When multiple analysis intervals are used an additional dimension is added to the canceling effect that was discussed in the comparison of the literal theory to the functional theory. As stated above, the separation of two potential concurrent delay events into different analysis intervals causes the functional theory to behave like the literal theory. Because the change from one period to another closes analysis for that period and mandates the identification and quantification of excusable, compensable and non-excusable delays for that period, it is only after all the analysis intervals, covering the entire duration of the project, are evaluated that reliable results can be obtained by performing a “grand total” calculation. In other words, the ultimate conclusion cannot be reached by selective evaluation of some, but not all, analysis intervals.65

5.4 ORDER OF INSERTION OR EXTRACTION OF DELAY EVENTS

The order of the insertion or extraction of the delays will affect the identification of potentially concurrent delays and the quantification of such concurrency. A common practice in the application of a Time Impact Analysis is to first insert the delay events that occurred in the first window, and then proceed to each successive window through to the completion of the Project through each successive window, to the last window. The delay events are inserted using a global basis or stepped basis in each successive schedule window.66 In the application of a As-Built But-For Analysis, the delay events are typically extracted in reverse chronological order starting with the last window, and then proceed to each previous window through to the start of the Project. The delay events are extracted using a global basis or stepped basis in each schedule window.

5.5 HINDSIGHT VS. “BLIND-SIGHT”

Prospective determination of concurrency during the project may be correct at the time, but may be incorrect in hindsight using retrospective information. Thus, in the context of schedule delay analysis, a difference may occur when reconciling the results utilizing full hindsight with results made “blind-sight” during the project when the actual start and finish dates of activities were unknown.

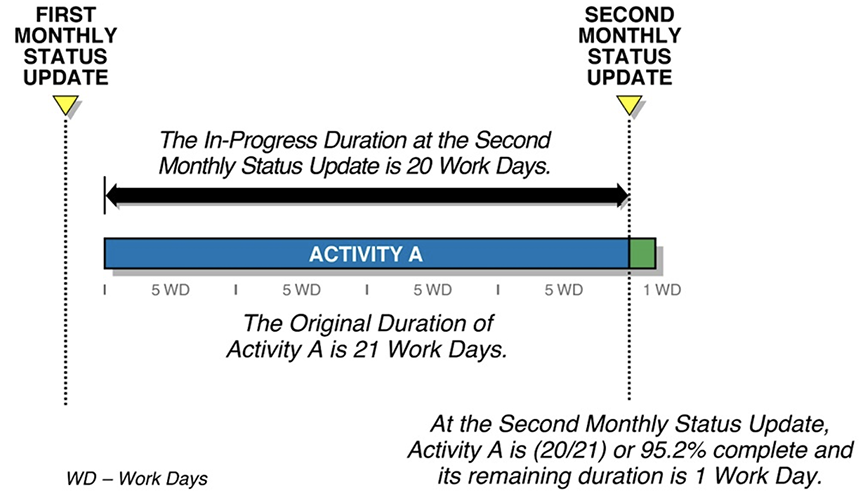

Figure 7 illustrates the Remaining Duration of an activity using the Blind-Sight method.

Figure 7

Blind-Sight Method for Determining Remaining Durations

of Activities in Progress at Each Schedule Update

In this example, Activity A has an original duration of 21 work days, starts several days after the first Monthly Status Update, and has been in progress 20 work days at the time of the second Monthly Status Update. Using the Blind-Sight method, and not knowing that any delay had occurred during the first 20 work days of progress, the remaining duration could be said to be only one work day at the time of the second Monthly Status Update. It would not be known until the activity was complete after the second Monthly Status Update that its as‑built duration was 25 work days.

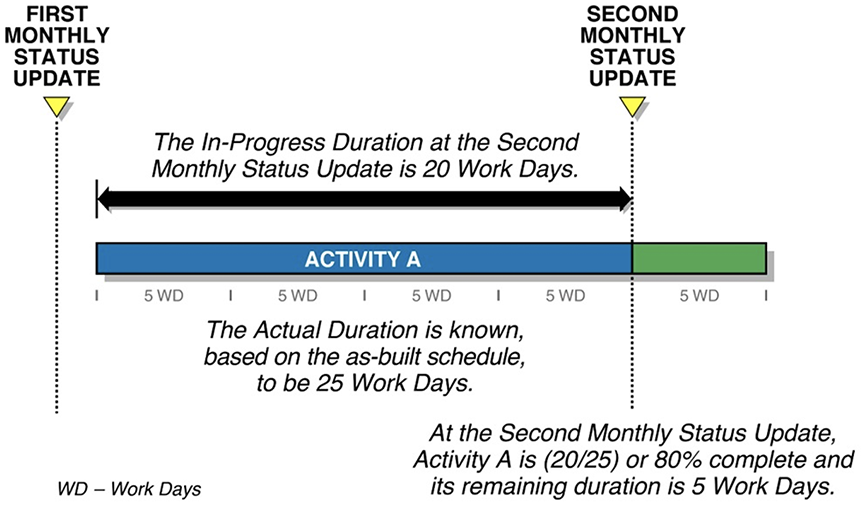

Figure 8 illustrates the Remaining Duration of an activity using the Hindsight method.

Figure 8

Hindsight Method for Determining Remaining Durations

of Activities in Progress at Each Schedule Update

In this example, the same Activity A, which had an original duration of 21 work days, starts several days after the first Monthly Status Update, and based on the as-built data, finishes with an actual duration of 25 work days. The second Monthly Status Update occurs after 20 work days of progress on Activity A have occurred. Therefore, Activity A is 80 percent complete at the second Monthly Status Update, and would have a Remaining Duration of 5 work days at that time.

This difference becomes technically relevant in the development of schedule updates at the beginning and end of each window. The assignment of the Remaining Duration to each partially progressed activity is highly dependent on whether the approach is hindsight or blind-sight. Because CPM calculations of the activity float values in the schedule updates depends, in part, on the value of the Remaining Durations of activities at the data date, the difference in approach will affect the identification and quantification of concurrent delays.67

Upon examination of the schedule networks on most projects, there are periods during which delays that were caused by either party would have delayed Project Completion. Thus, concurrent delay often occurs. Under a dominant cause argument, the contractor would have to prove that the owner-caused delays were the dominant cause of delay and that the contractor-caused delays were minor and not dominant, or that the concurrent contractor-caused delays were pacing delays, for which there is evidence of intentional slowing down of the other work by the contractor because of owner-caused delays.

Because certain work must be performed in a given sequence on an engineering and construction project, and often more than one predecessor activity must be completed before a successor activity can be performed, the dominant cause theory is of little benefit when work on each predecessor activity must be completed before the successor activity can proceed. Thus, if both predecessor activities have delays, one caused by the owner and one caused by the contractor, the use of the dominant cause theory is subjective and does not adequately consider physical requirements of sequencing engineering and construction work.

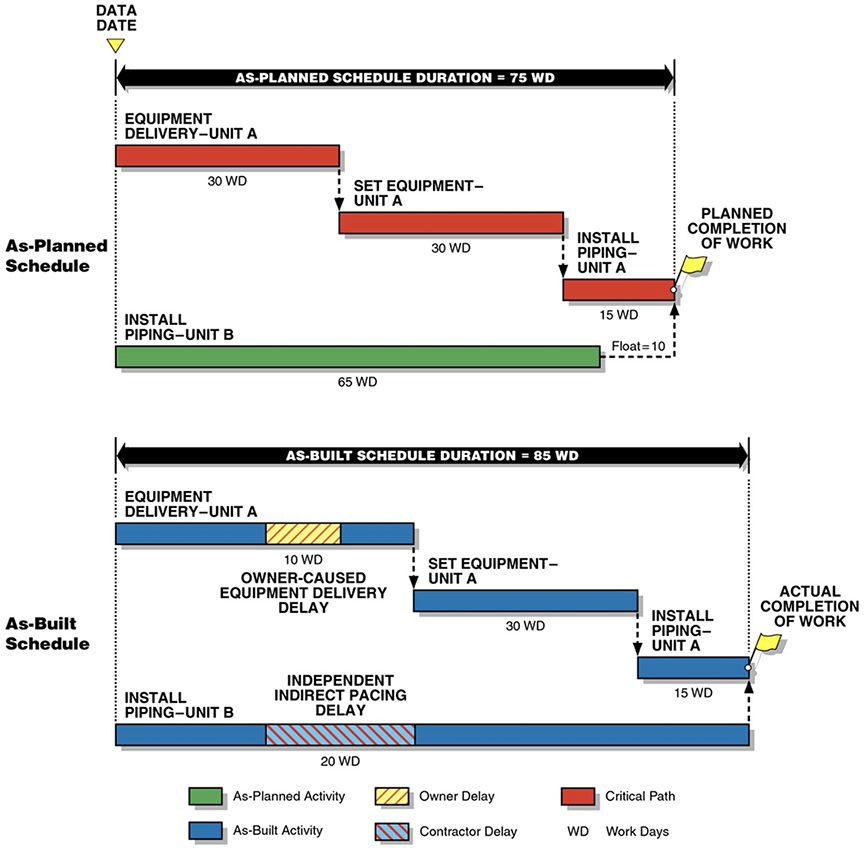

6. PACING VS. CONCURRENT DELAY

Pacing delay occurs when the delay in one activity occurs, and a conscious and contemporaneous decision is made by the contractor to pace progress in a second and independent activity, or several activities. Thus, the contractor deliberately slowed down its work. However, concurrent delay results when the work in a second and independent activity, or several activities, is involuntarily delayed by factors independent of any problems arising from the delay in another activity.

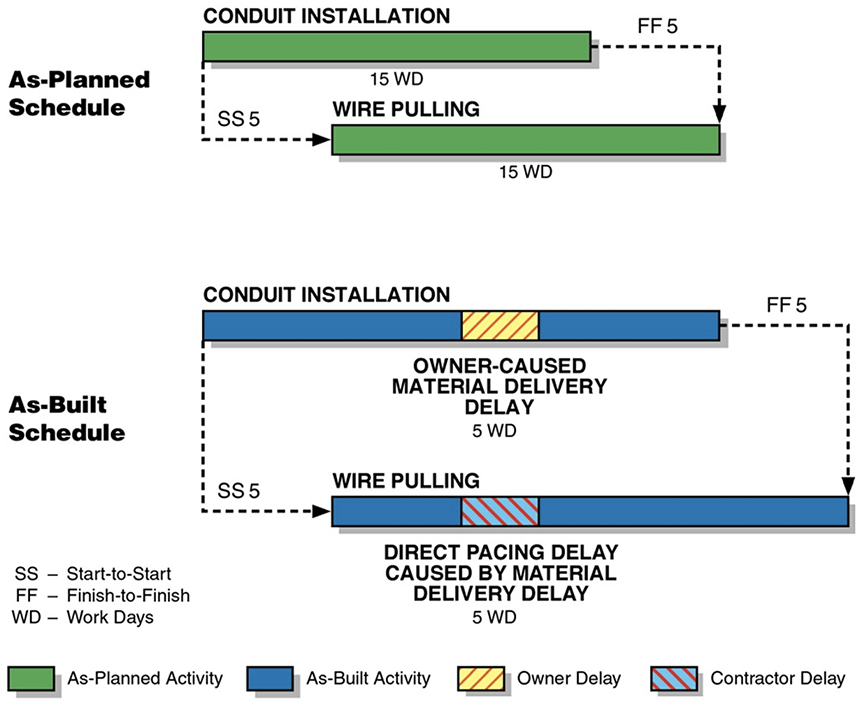

Pacing is typically manifested in two distinct circumstances.

- One situation, called direct pacing, is where the duration of a successor schedule activity is extended due to a delay in a predecessor activity on which the progress of the successor activity is directly dependent. As shown in Figure 9, the duration of the wire pulling work is extended in duration because the installation of conduit work is taking longer due to the lack of conduit material. While this is pacing, it is not considered a concurrent delay – the cause of one delay is the result of the other delay. Examination of activity relationships in the schedule, usually in the form of finish-to-finish ties, will provide the information to determine if direct pacing has occurred.

Figure 9

Illustration of Direct Pacing

- In the second situation, called indirect pacing, the paced activity has no dependency on the other activity. As shown in Figure 10, the contractor deliberately slows down its piping installation work in Unit B because of the owner’s delay in equipment delivery in Unit A. The equipment delivery delay creates68 available float to be consumed by the piping installation in Unit B activity.

Figure 10

Illustration of Indirect Pacing

If proper documentation exists, pacing can be a defense to a potential concurrent delay and it is not a distinct delay event. Therefore, the pacing issue is relevant only to the extent that concurrency of delays is an issue.

The contractor enjoys the right to pace its work along with the view that float is a shared resource that is to be used by the party who first needs the float. However, lack of resources69 which should have been provided by the contractor, or poor productivity that was caused by the contractor and which caused other independent activities to be delayed, are not considered pacing delays. These are contractor-caused problems, and the contractor is responsible for the delay and disruption that are caused by these problems.

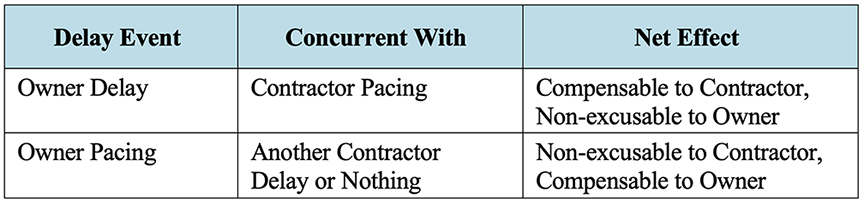

Pacing may alter the net effect of the compensability of a concurrent delay situation, as shown in Table 3 below:

Table 3

Net Effect of Pacing Delays

In its evaluation of potential concurrent delay vs. a pacing delay, the following generally accepted international construction industry guidelines apply,70 in order of importance, as follows:

- A predecessor dependent parent delay must precede a pacing delay;

- The contractor needs to demonstrate that it could resume progress at an un‑paced rate; and

- The contractor needs to provide evidence that a conscious and deliberate decision was made at the time to pace the work as a result of the other delay.

Pacing can be contentious because it can be used to excuse delay which is otherwise unaffected by a change in scope or variation. Thus it can be said that:

Pacing arguments are most often made at the end of a project, when an as-built programme analysis reveals that activities which were not affected by any employer instructed variations or other excusable events appear to have been delayed. When pacing is argued with hindsight, it should be treated with both caution and skepticism, especially when the assertion is unsupported by contemporaneous records.71

If no documentation is made available to justify a pacing delay, then consistent with the AACE International recommended practice, concurrent delays by the contractor should not be regarded as pacing delays, and instead are delays for which the contractor is responsible.

7. PRACTICAL GUIDELINES FOR CONCURRENT DELAY IN CONSTRUCTION CONTRACTS & ANALYSIS OF CLAIMS

The parties must first be guided by the clauses in their contract or referenced documents regarding the handling of time extensions, concurrent delay, excusable delay, compensable delay, and liquidated damages. If specific provisions regarding these issues are not included in the contract or referenced documents, the following practical guidelines with respect to dealing with these issues are provided:

- Use a windows-based CPM schedule analysis to determine if the contractor is entitled to a time extension as a result of excusable delays to the then critical path of the project at the time that the excusable delays occurred.

- If the actual project delay is greater than the amount of time extension to which the contractor is entitled, then the owner may be entitled to receive liquidated or actual damages if no liquidated damages are stated in the contract for the additional contractor-caused delays.

- Use a windows-based CPM schedule analysis to determine if the contractor is entitled to additional compensation for time-related costs as a result of compensable construction delay claims to the then critical path of the project at the time that the compensable delays occurred.

- If the contractor can demonstrate that it was effectively delayed by an owner responsible event and the owner can demonstrate that the project was also concurrently delayed by an event which was caused by the contractor or actions for which the contractor is responsible, the contractor may nevertheless be entitled to an extension of time for the full amount of such owner responsible delay unless otherwise stated in the contract between the parties.

- In considering whether owner responsible events have also “caused” the project delay, the principles of causation should be examined, and certain causes of delay, that while sequential or parallel are not of equal causative persuasion, may need to be excluded. If the occurrence of an owner event is merely coincidental and simply provides a slippage to minor work rather than the true cause for the project delay, there may be no extension of time entitlement and the owner may be entitled to liquidated or actual damages.

- In considering whether contractor-caused events or actions for which the contractor is responsible have also “caused” the project delay, the principles of causation should also be examined, and certain causes of delay, that while sequential or parallel are not of equal causative persuasion, may need to be excluded. If the occurrence of a contractor-caused event is merely coincidental and simply provides a slippage to minor work rather than the true cause for the project delay, there may be no liquidated damages entitlement and the contractor may be entitled to its time-related costs for the period of delay.

- If it is established that the cause of the delay is attributable to owner (i.e., there is no true concurrent delay or after considering the effect of concurrent delay), and if the contractor has complied with the notice provisions and the duty to mitigate any delay, the amount of time extension and/or the reimbursement of the contractor’s time-related costs should be dealt with pursuant to the Change Orders clause or other contractual provisions, and if not agreed, dealt with pursuant to the Dispute Resolution and Arbitration clause.

- If functional or literal concurrent delay arises, subject to a CPM schedule analysis to otherwise allocate delay, the contractor may be entitled to a time extension for the period of the concurrent delay, but no time-related costs for that period unless otherwise stated in the contract.

About the Author

Richard J. Long, P.E., P.Eng., is Founder of Long International, Inc. Mr. Long has over 50 years of U.S. and international engineering, construction, and management consulting experience involving construction contract disputes analysis and resolution, arbitration and litigation support and expert testimony, project management, engineering and construction management, cost and schedule control, and process engineering. As an internationally recognized expert in the analysis and resolution of complex construction disputes for over 35 years, Mr. Long has served as the lead expert on over 300 projects having claims ranging in size from US$100,000 to over US$2 billion. He has presented and published numerous articles on the subjects of claims analysis, entitlement issues, CPM schedule and damages analyses, and claims prevention. Mr. Long earned a B.S. in Chemical Engineering from the University of Pittsburgh in 1970 and an M.S. in Chemical and Petroleum Refining Engineering from the Colorado School of Mines in 1974. Mr. Long is based in Littleton, Colorado and can be contacted at rlong@long-intl.com and (303) 972-2443.

1 The term “window” refers to a period of time between two dates in the schedule. The date that define the start or end of a window is called a data date, which is the date on which the schedule is updated for progress.

2 The term “owner” is applied generically throughout this article for the analysis of issues applicable to the owner or employer of a project.

3 The term “contractor” is applied generically for the analysis of issues applicable to the contractor of a project.

4 If the parallel activity paths are not equally critical, then the duration of each party’s delay and the float value of the affected activities would need to be examined to determine the amount of concurrent delay, if any.

5 See Royal Brompton Hospital NHS Trust v. Frederick A Hammond (No.1), [2000] EWHC technology 39 at 31.

6 See L.L. Hall Construction Company v. United States, 379 F.2d 559, 564 (Ct. Cl. 1966); Gasparini Excavating Company v. Pennsylvania Turnpike Commission, 187 A. 2d 157 162 (Pa. 1963); Felhaber Corporation v. New York, 410 N.Y.S. 2d 920, 924, 927 (App. Div. 1978); J.A. Jones Constr. Co. v. City of Dover, 372 A.2d 540 (Del. Super. Ct.) aff’d, 377 A.2d 1(1977); Luria Bros. & Co. v. United States, 369 F.2d 701,707 177 Ct. Cl. 676 (1966); J. D. Hedin Constr. Co. v. United States, 347 F.2d 235, 258, 171 Ct. Cl. 70 (1965).

7 See Cocklin, Matthew, “International Approaches to the Legal Analysis of Concurrent Delay: Is there a Solution for English Law?,” Society of Construction Law, April 2013, p. 9.

8 See Jefferson Hotel Co v. Brumbaugh, 168 F 867 (4th Cir 1909).

9 See Greenfield Tap & Die Corp v. US 167, Ct.Cl. 529, 338 F2d 81 (1964) pp. 87 and 90.

10 See Calumet Construction v. Metropolitan Sanitary District of Greater Chicago, 178 Ill. App. 3d 415 N.E.2d (1988) p. 420.

11 See Coath & Goss Inc. v. U.S., 101 Ct.Cl. 702 (1944) pp. 714-715.

12 See PCL Construction Services v. U.S., 47 Fed.Cl. 745 (2000).

13 See Blinderman Construction Co v. The United States, 695F.2d 552 (10 December 1982).

14 See Appeal of Beckman Construction Company, ASBCA No. 24725 (8 February 1983).

15 See Appeal of Cline Construction Company, ASBCA No. 28600 (23 August 1984).

16 See Toombs v. the United States, 4 Cl. Ct. 535 (1984).

17 See William F. Klingensmith Inc. v. United States,731 F.2d 805 (19 March 1984).

18 See Appeal of Rivera General Contracting, ASBCA No. 25888 (30 April 1985).

19 See Appeal of Hood Plumbing, AGBCA No. 84-181-1 (28 October 1987).

20 See Appeal of C.G. Norton Co. Inc., ENG BCA No. 5182 (19 January 1988).

21 See AMEC Processing Equipment Co. v. United States, 171 Ct. Cl. 324, 347 F.2d 509 (1965).

22 See Calumet Construction Corporation v. Metropolitan Sanitary District of Greater Chicago, 178 Ill.App.3d 415,533 N.E.2d 453 (30 December 1988).

23 See Appeal of Volpe-Head (Joint Venture), ENG BCA No. 4726 (14 July 1989). Again, the contract contained an adjustment of price clause similar to that in Blinderman.

24 See Commerce International v. United States, 167 Ct. Cl. 529, 338 F.2d.81, 90 (1964).

25 See Wilner Construction Co. v. The United States, 23 Cl. Ct. 241 (1991).

26 See Appeal of B.D. Collins Construction Company, ASBCA No. 42662 (17 December 1991).

27 See Appeal of JBL Construction Company Inc., VABCA No, 1799 (7 November 1985).

28 See Appeal of Coffey Construction Company Inc., VABCA No. 3661 (11 February 1993).

29 See Smith v. The United States, 34 Fed. Cl. 313 (25 October 1995).

30 See Multiplex Constructions (UK) Ltd. v. Honeywell Control Systems Ltd., [2007] EWHC 447 (TCC), [2007] BLR 195, 111 Con LR 78, [2007] CILL 2458, para. 47.

31 See H. Fairweather & Co Ltd. v. London Borough of Wandsworth, (1987) 39 BLR 106 (OR).

32 See Henry Boot Construction (UK) Ltd. v. Malmaison Hotel (Manchester) Ltd., (1999) 70 Con LR 32 (TCC).

33 “Keating on Construction Contracts,” 9th Edition, Sweet & Maxwell, 2012, paras. 9-062 – 9-066.

34 The Society of Construction Law Delay and Disruption Protocol, Oxford, October 2002, Section 1.4.1.

35 See City Inn Ltd. v. Shepherd Construction Ltd., [2007] CSOH 190, [2008] BLR 269, (2008) 24 Constr LR 590; and on appeal [2010] CSIH 68, 2011 SC 127, 2011 SCLR 70, [2010] BLR 473, 136 Con LR 5.

36 See Cocklin, p. 11.

37 Id. at 13.

38 See Australian Standards (AS) 2124-1992, clause 35.3.

39 See Cocklin, p. 16. Also see W. Hing Construction Co. Ltd. v. Boost Investments Ltd., [2009] BLR, High Court of Hong Kong.

40 See Tobin, Paul, “Concurrent and Sequential Causes of Delay,” 2007, 24 ICLR 142.

41 See Pickavance, Keith, Delay and Disruption in Construction Contracts, 3rd ed., T&F Informa (UK) Ltd, London, 2005, pp. 644-645, paragraph 16.91.

42 Id. at p. 624, paragraph 16.19.

43 Barnes, R, 2003, Easing the Agony, 14 April 2008. See http://www.building.co.uk/ story.asp?sectioncode=57&storycode=1025760.

44 Bingham, T., Getting in Early, 14 April 2008, See http://www.building.co.uk/story.asp?sectioncode=57&storycode=1014742.

45 AACE International Recommended Practice No. 29R-03 Forensic Schedule Analysis, 25 April 2011, Section 4.2.D.2, p. 106. Also see Section 5.1 herein.

46 As-Built Calculation Schedules can be developed for use in the performance of an As-Built But-For analysis of owner-caused impacts. When actual dates are used to update a schedule for work that started and/or finished during a window, the actual dates override the schedule logic, and the start and finish dates of the activities are fixed regardless of the logic. Therefore, the as-built critical path and float values for the work performed during the window, which can only be determined from the schedule logic, are not provided by the software calculations for the work that was performed during a window. Only the critical path and float values are determined for work yet to be performed after the end of the window. However, the early/late start and early/late finish dates in an As-Built Calculation Schedule are driven by the schedule logic and the original or remaining durations of the schedule activities. The as-built logic and driving lag values are programmed into the As-Built Calculation Schedule such that it generates the same early start and early finish dates for activities that actually started and finished during each window. The As-Built Calculation Schedules also contain the same forecasted start and finish dates for activities beyond the end of the windows that are contained in the statused schedules for each window.

47 AACE International notes that “the forensic scheduling analyst may not possess the skill, knowledge, or experience to independently determine the legal liability for an event. In such a case, the first step consists of making a reasoned assumption of liability subject to verification by those with the requisite expertise.”

48 AACE International Recommended Practice No. 29R-03 Forensic Schedule Analysis, 25 April 2011, Section 4.1.B, p. 99.

49 Id., adapted from Figure 12- Net Effect Matrix-Concurrent Delay, p. 100.

50 Adapted from AACE International Recommended Practice No. 29R-03 Forensic Schedule Analysis, 25 April 2011, Figure 15- Net Effect of Potential Concurrent Delay Combinations, p. 111.

51 Id., Section 4.1. C, pp. 100-101.

52 The Society of Construction Law Delay and Disruption Protocol, Oxford, October 2002.

53 Id. at p. 3 (B).

54 Id. at Section 1.4.4.

55 Id. at Section 1.4.1.

56 Id. at Section 1.4.7.

57 Id. at Section 1.10.1.

58 Id. at Section 1.10.4.

59 In England, simply stated, the delay event attributable to the owner must be the effective, dominant cause of the delay for the contractor to be entitled to compensation. See Furst, Q.C., Stephen and The Honorable Sir Vivian Ramsey, M.A., Keating on Construction Contracts, 8th Edition, Sweet & Maxwell Limited, 2006, paragraph 8−019.

60 AACE International Recommended Practice No. 29R-03 Forensic Schedule Analysis, 25 April 2011, Section 4.2.D.1, p. 105.

61 The Duration Variance Table identifies the change in the activity durations at the end of the window compared to the planned durations of activities at the start of the window. The Lag Variance Table identifies the change in the activity relationship values at the end of a window compared to the activity relationships at the start of the window.

62 AACE International Recommended Practice No. 29R-03 Forensic Schedule Analysis, 25 April 2011, Section 4.2.D.3, p. 107.

63 Id. at Section 4.2.D.4.a, p. 107.

64 Id. at Section 4.2.D.4.b, p. 108.

65 Id. at Section 4.2.D.4.a, pp. 107-108.

66 Id. at Section 1.4.E.2, p. 108.

67 There is no prevailing practice, let alone agreement, on which practice for determining remaining durations, hindsight or blind-sight, ought to be used in the reconstruction of schedule updates.

68 The term “creation” should not be interpreted to mean that total float is increased. In fact, the opposite is true. The parent delay adversely impacts the overall critical path of the project, thereby decreasing total float. What it creates (increases) is relative total float on the path of the paced activity relative to the total float on the path carrying the parent delay.

69 In some analyses, lack of resources could be considered a pacing delay if the amount of resources caused by owner-caused change orders is significantly greater than the resources required for the base scope of work.

70 AACE International Recommended Practice No. 29R-03 Forensic Schedule Analysis, 25 April 2011, Section 4.2.G, p. 113. It does not appear that the SCL has addressed pacing.

71 See Keane, P.J. and A.F. Caletka, Delay Analysis in Construction Contracts, Wiley-Blackwell, 2008, Section 5.3.7, p. 213.

Copyright © Long International, Inc.

ADDITIONAL RESOURCES

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE