Forensic Schedule Assurance Review: A Vital Step Before Starting a Detailed Schedule Analysis

This article discusses practical advice on how to rectify common problems with project schedules by performing a forensic schedule quality assurance review before starting any detailed schedule analysis.

1. INTRODUCTION

Important time management actions are decisions which depend upon reliable and accurate information. Effective scheduling is needed to properly measure progress, determine the effect of changes in scope, and accurately forecast the completion of contractual milestone dates. A project schedule must accurately reflect the scope or work, have sufficient detail to monitor progress, and contain activity relationships that properly define the work sequences.

Unfortunately, many project schedules are often poorly prepared and require extensive re-baselining during project execution to become a useful project management tool to properly execute the time management aspects for the project such as measuring progress, determining the effects of changes in scope, and forecasting the completion of contractual milestones and the overall project completion dates. In terms of contract claims and disputes, poorly prepared schedules do not provide a reliable tool to measure the amount and responsibility for delays, provide a basis for a time extension, or assess the need to accelerate the schedule or re-sequence the work to mitigate delays.

To rectify these common problems with project schedules, forensic schedule quality assurance reviews are essential before starting any detailed schedule analysis.

2. REASONS FOR FORENSIC SCHEDULE ANALYSIS

Traditionally used for planning, scheduling, and monitoring project execution, Critical Path Method (CPM) scheduling techniques are also applied in forensic claims analysis to determine the causes, responsibilities, and liabilities for project delays, disruption or acceleration. This may include a prospective or forward looking method which uses the contemporaneous schedules to forecast the impact from a current or future event. It may also include an historical or backward looking method which uses the as-built schedule. The reasons for performing a forensic schedule analysis can be numerous and often concern the following issues:

- Relief from liquidated damages;

- Justification for a time extension;

- Proof of delay mitigation;

- Change Order impact to the critical path (i.e., fragnet analysis);

- Proof of concurrent delay versus contractor “pacing;”

- Demonstration of schedule acceleration (i.e., Time Impact Analysis results compared to as-built schedule); and

- Recovery of compensable delay.

Forensic schedule analysis is broadly defined as the investigation, quantification, and assignment of delay responsibility for critical path slippage based on what actually happened on the project. A key element of proof for contract disputes due to schedule delay and schedule impacts is based on the contemporaneous project schedules. If the basic scheduling model is flawed and contains numerous deficiencies, then any results or conclusions based on the flawed and deficient model are suspect and potentially unreliable.

Before starting a detailed schedule analysis, a crucial step is to perform forensic quality assurance reviews to ensure that the model used to measure and allocate delay is reasonable and free of obvious or hidden deficiencies. In the following sections, this paper discusses: 1) why changes occur on projects; 2) how to identify contract entitlements; 3) how to establish cause-effect links; 4) common issues causing delays and impacts; 5) types of forensic schedule analysis methods; and 6) the assessment of schedule quality assurance and integrity.

3. CHANGE OCCURS ON ALMOST EVERY PROJECT

Whether small or large, change occurs on almost every project and, typically, all changes cause some type of cost or schedule impact. For instance, an owner may want to add an enhancement to the original scope. An action or inaction by one or both of the contracting parties can result in an impact. A natural disaster such as an earthquake, hurricane, or tsunami may directly or indirectly cause delay to the project. Technical complexities, the increasing contentious nature of the contract environment, tight competitive bids, and owners with tough-minded and sometimes inequitable contractual attitudes may also be contributors to delay and impact.

Moreover, today’s marketplace contains risk elements that go beyond the performance of the work. These risks relate to factors that impinge on the performance of work and, thus, can cause a substantial increase in the time and cost of contract performance. Project risks may include but are not limited to the following:

- Contract documents generate adversarial roles and inhibit the development of teamwork;

- Project cost and schedule control systems are often not sufficiently sophisticated or integrated;

- Contract administration often does not recognize the express and implied terms of the contract;

- Regulatory control is complex and produces unfavorable economic conditions;

- Environmental considerations can produce severe time delays to the commencement and completion of the work;

- Building codes may be out-of-date, inapplicable, and non-uniform;

- Complex union agreements inhibit resource allocation and optimization;

- Design engineers untrained in construction contract issues often masquerade as construction managers;

- The legal process focuses on blame and inhibits problems solving;

- Sociological and political factors create major project delays; and

- Project management systems and procedures are often not state-of-the-art practices.

Moreover, the disputes that often arise from engineering and construction contracts can involve complex technical and legal issues.1 The question is: Does the contractor have any entitlement? Entitlement is the legal basis of the claim. Entitlement may be derived from the language of the contract (for example, the Changes Clause) or the principles of tort law, which set forth the duties and responsibilities of the individual (for example, implied warranties).

In practice, a thorough understanding of construction contract entitlement is a mandatory prerequisite to the identification of issues on a project that give rise to a contractor’s recovery of increased time and cost of performance. This understanding is also necessary for the analysis and preparation of a claim.

4. CONTRACT ENTITLEMENTS IDENTIFIED

Emerging from the U.S. and state courts, and generally applicable in foreign jurisdictions, 19 basic construction claim entitlements are recognized for the recovery of project delays and subsequent damages. These entitlement types, with brief commentary, are summarized below:

- Acceleration – Performance of the contract work in a time period shorter than that originally contemplated by the contract or performing on time when the contractor is entitled to an extension of time for performance.

- Acts of God/Weather – Typically good for a time extension only if the conditions vary substantially from the norm.

- Cardinal Change – A change that is outside the scope of the contract.

- Constructive Change – The owner’s action or inaction has the same effect as a written directive.

- Defective and Deficient Contract Documents – “If the contractor is bound to build according to plans and specifications prepared by the owner, the contractor will not be responsible for the consequences of defects in the plans and specifications. This responsibility of the owner is not overcome by the usual clauses requiring the contractor to visit the site, to check the plans, and to inform themselves of the requirements of the work.”2

- Delays – Problems beyond the control and without the fault or negligence of the contractor that prevent the contractor from proceeding with any part of the work.

- Differing Site Conditions – Two types: (1) subsurface or latent physical conditions at the site differing materially from those indicated in the contract; and (2) unknown conditions at the site of an unusual nature.

- Directed Change – The owner enjoys the right to make any change that generally falls within the scope of the contract.

- Disruption – Any change in the method of performance or planned work sequence contemplated by the contractor at the time the job was bid that prevents the contractor from actually performing its work in that manner.

- Implied Warranty – The implied provision of every contract, that neither party will do anything to prevent performance thereof by the other party, or that will hinder or delay their performance.3

- Impossibility of Performance – Two types: (1) physical impossibility such as the design drawings defy the law of gravity; and (2) economic impossibility such as the case when a contractor cannot continue to finance a blizzard of unresolved change orders.

- Maladministration – Based on the implied warranty that the owner will not, by its actions or inactions, unreasonably interfere with the contractor’s right to develop and enjoy least-cost performance.

- Owner-Furnished Items – The owner’s failure to furnish items in accordance with bid phase promises.

- Strikes – Typically good only for a time extension unless the other party precipitated the strike.

- Superior Knowledge – The owner’s withholding, during the bid phase, of specific data on matters of substance.

- Suspension – The owner’s directive that work be stopped on a part or the whole of the contract.

- Termination – Two types: (1) termination for convenience resulting from factors outside the contract; and (2) termination for default when a contractor’s performance is not acceptable.

- Unjust Enrichment – The doctrine of unjust enrichment provides that a “person shall not be allowed to profit or enrich himself inequitably at another’s expense.”

- Variation in Quantities – Of prime importance to the contractor is whether its unit prices are sufficient to cover its overhead and other costs if the number of units significantly changes from the owner’s estimated quantities used to prepare the contractor’s bid.

On a heavily disrupted project, one or a combination of several of the above entitlements may provide to the contractor the contractual basis for compensation for the increased cost of the work or extended duration of performance. The contractor then has the obligation to make a request for equitable adjustment for extra work or extra time in excess of the contractor’s original scope, cost, and schedule.

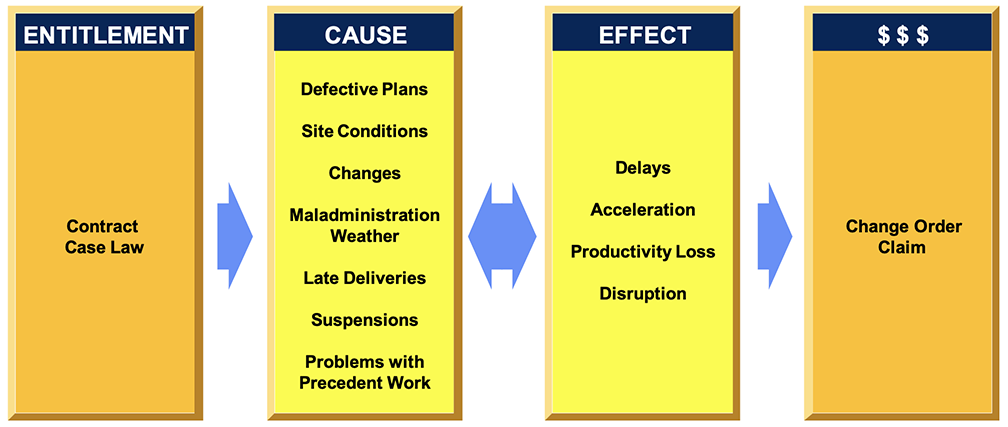

5. ESTABLISHING THE CAUSE-EFFECT LINK

A contractor’s claim request must clearly identify what actions or inactions by the owner caused the compensable liability and which of the entitlements for the contract problem bear a direct relationship to the financial loss or schedule impact. This establishes the all important cause-effect link that is necessary to support a construction claim, as shown in Figure 1 below:

Figure 1

The Cause-Effect Link

The contract documents typically specify contract clauses and dispute resolution procedures required for submission of claims. Important sections of the contract documents may include the changes clause, delay to the critical path requirements, order-of-precedence for contract documents, coordination clause, weather clause, no damage for delay clause, and timely notice requirements.

If the contractor does not comply with the stipulated requirements, a contractor’s legitimate change order request or claim may be rendered invalid and rejected due to lack of contract compliance. All contractor claims must be supported by contemporaneous project records and documentation. More specifically, the crucial element of proof needed for delay claims should be based on the contemporaneous project schedules used to execute the work.

6. COMMON ISSUES CAUSING IMPACT AND DELAY

Owners, engineers, construction managers, and contractors have the best of intentions when they initiate a project. The owner wants a profitable state-of-the-art facility, the engineer desires to create the owner’s intent in its design, the construction manager agrees to manage the quality, safety, cost and schedule objectives of the owner, and the contractor wants to build the facility on time and make a reasonable profit. Then the parties sign a contract and everything changes.

Too many projects are transformed from the best of intentions into highly impacted projects that are out of control and headed for claims and disputes. Claims are most often initiated by contractors against owners due to a multitude of owner actions or inactions. Some of the typical owner actions or inactions that can create cost and schedule impacts are included in Table 1:

Table 1

Examples of Typical Owner-Caused Issues that Create Cost and Schedule Impacts

| Issue No. | Description |

| 1 | Late Engineering and Design Information |

| 2 | Numerous and Late Design Changes |

| 3 | Late Delivery of Owner-Furnished Equipment |

| 4 | Defective Owner-Furnished Equipment |

| 5 | Impact from Other Contractors Due to Multi-Prime Projects |

| 6 | Slow Approval of Contractor Submittals |

| 7 | Late Response to Contractor Requests for Information (RFIs) |

| 8 | Overzealous Inspections by Owner’s Agents |

| 9 | Untimely Approval of Valid Contractor Changes |

A contractor must demonstrate through a cause-effect analysis how one or many of these issues caused a cost or schedule impact to the contractor’s project baseline schedule or schedule update as supported by contemporaneous project records. In addition, it is also important to evaluate the timing of issues as well as potential impacts to the critical path, if any.

For example, in one case, a contractor was claiming late owner equipment deliveries during a discrete period of time that the contractor alleged caused extensive project delay and productivity loss. Based on the timing of the alleged late equipment deliveries, it was confirmed that the contractor’s schedule updates reported minimal overall project slippage and the contractor’s monthly reports reported good field productivity. Therefore, the contractor’s claims were unsupported. If a contractor is seeking a time extension due to an owner-caused issue, a contractor must identify the time when an issue started and finished and how it impacted ongoing or subsequent work activities in terms of cost and schedule.

However, it is important to note that contractors are very rarely, if ever, perfect, and they will most likely have their own set of internal problems, execution errors, and rework issues that occur during the project. In many cases, contractor-caused issues are concurrent and offsetting to owner-caused issues and delays that must be considered when a contractor is asserting a global delay and disruption claim. Some common types of contractor-related delays and impacts are included in the following Table 2:

Table 2

Examples of Typical Contract-Caused Issues that Create Cost and Schedule Impacts

| Issue No. | Description |

| 1 | Bid Errors |

| 2 | Subcontractor Default and Replacement |

| 3 | Fabrication and Installation Errors and Rework |

| 4 | Change In Execution Sequence |

| 5 | Poor Field Productivity |

| 6 | Field Labor Absenteeism and Tardiness |

| 7 | Holiday Slowdowns |

| 8 | Late Installed Equipment and Material Deliveries |

| 9 | Problems with the Contractor’s Construction Equipment |

| 10 | Defective Contractor Scheduling |

| 11 | System Turnover Noncompliance |

Failure by a contractor to account for its own deficiencies drastically reduces the overall creditability of a contractor’s claim position and may render the contractor’s calculation of results unreliable. A contractor’s claim must be supported by contemporaneous project records and documentation, and the quantification and allocation of responsibility by both parties for cost and schedule impacts and delay is necessary. More specifically, the crucial contemporaneous project records required to prove delays claims are contained within the contractor’s project schedules.

7. MANY DIFFERENT TYPES OF FORENSIC SCHEDULE ANALYSIS METHODS EXIST

Over the past 40 years, many variations of forensic delay analysis methodologies and approaches have been developed and utilized for analyzing schedule performance and schedule delay. AACE International’s Recommended Practice 29R-03, most recently issued on April 25, 2011, identifies and discusses nine different schedule analysis methods and protocols documenting the basic technical principles and guidelines for applying each type of analysis. Several of the more well-known forensic schedule analysis methods are listed below:4

- Static As-Planned versus As-Built

- Windows Analysis

- Contemporaneous Period Analysis

- Impacted As-Planned

- Time Impact Analysis

- Collapsed As-Built

Some of these analysis methods are observational and qualitative while other methods are modeled and quantitative. Depending on the size of the schedule and complexity of the issues, the process for performing a forensic schedule analysis can quickly become complex. Each method has advantages and disadvantages with varying degrees of effort and associated costs, and should be carefully selected.

For example, an observational method typically includes analyzing the baseline schedule, schedule updates, and as‑built schedule to observe and identify delayed activities and then determine which party is responsible for delays. A simple and static plan versus as-built comparison is an example of an observational approach. Although considered more subjective in nature, this type of approach uses static schedule comparisons and usually requires less time and less cost to perform. This approach works well when very few impacts or delays affected the schedule and the impacts and delays occurred at or near the start of the work.

A modeled approach is similar to the observational method, but known delays are either added to the schedule to create impact models where liability and allocation of delay responsibility are quantified or known delays are subtracted from the schedule to determine the completion date if the delays had not occurred. A modeled approach is more objective and structured in terms of measuring delays by analyzing slippages to the critical path at various points of time during project execution. Examples of quantitative analysis include, but are not limited to, the Time Impact Analysis (TIA)5 or the As-Built But-For (Collapsed As-Built) Analysis.

Modeled methods are traditionally used when multiple and overlapping delay issues have affected the project and where both the owner and contractor contributed to the delay. These analyses typically require more time and cost to perform. Quantitative schedule analyses are typically required for legal proceedings. Method selection must be based on consideration of both the technical and factual information. Therefore, before starting a schedule delay analysis, it is important to review and consider several key factors prior to selecting an appropriate schedule delay analysis methodology.

8. ASSESSMENT OF SCHEDULE QUALITY AND INTEGRITY IS NEEDED AT THE START

The underlying foundation for developing a supportable forensic schedule analysis depends on the quality and reasonableness of the project schedules. Many change orders and claims have time-related costs which are schedule driven. Since the project schedule is the key management tool for measuring project progress over time, then the project schedule should accurately reflect the impact on specific scopes of work, logic relationships, milestones, and completion work.

Checking the integrity of project schedule for obvious deficiencies is vital to ensure that the model is accurate and reasonable. If significant deficiencies exist, then the model used to measure, allocate, and assign critical path slippage could be flawed, and any resulting conclusions regarding the schedule analysis could be rendered unreliable. Some vital schedule issues to evaluate include the following: 1) determine if the schedule complies with the contract documents; 2) ensure that the original contract scope and approved change orders are accurately reflected in the schedule; 3) evaluate schedule metrics to gauge schedule integrity; and 4) compare schedule updates to the baseline schedule to identify significant changes.6 Therefore, it is important when evaluating the quality and reasonableness of project schedules to look for deficiencies in the areas as discussed in the following sections.

8.1 REVIEW AND UNDERSTANDING OF CONTRACT DOCUMENTS

An essential starting point is a thorough review and understanding of the contract documents. It is important to fully understand what documents and drawings are included and how they work together to define the scope of work. The various terms and conditions, instructions, and other documents that define the various contract administration procedures, notice requirements, responsibilities, and other contractual duties should be considered.7

More specifically, the contract documents will likely define, dictate, limit, or at least influence the direction of a schedule delay analyst and the selection of the appropriate forensic schedule analysis methodology. Other contract clauses and requirements that need consideration regarding schedule delay and related issues are summarized in Table 3 below:

Table 3

Other Contract Clauses and Requirements that Require Consideration

Regarding Schedule Delay and Related Issues

| Item No. | Contract Clause | Item No. | Contract Clause | |

| 1 | Contract Modifications | 8 | Contractor Progress | |

| 2 | Changes | 9 | No Damages for Delay | |

| 3 | Coordination | 10 | Time Extensions | |

| 4 | Inspection of Site Conditions | 11 | Mechanical Completion | |

| 5 | Differing Site Conditions | 12 | Weather | |

| 6 | Ownership of Float | 13 | Flow-Down Requirements | |

| 7 | Liquidated Damages | 14 | Timely Notice |

Certain contracts require that the contractor identify all approved change order work as new schedule activities with logic ties to existing activities in the schedule. In addition, the contractor must identify the actual time of performance of all approved change order work in the schedule. Based on the requirements of the contract documents, the contemporaneous project schedules must be reviewed for contract compliance. However, it is not uncommon to find that some or all of the contemporaneous project schedules require adjustments in order for the schedules to be compliant with contract requirements.

8.2 MISSING ORIGINAL SCOPE

An important quality check is to ensure that the complete original scope is represented in the project schedule. On large and complex projects, it is not unusual to find some of the original contract scope to be missing and accidentally excluded from the baseline schedule. This is especially the case when a rolling wave schedule development technique is utilized by the contractor. Therefore, it is important to verify to the extent possible that all required contract scope is represented in the baseline schedule. This is done by going through a verification process of the contract documents and other available project information to determine that the schedule accurately reflects the contractual Scope of Work. Areas for review may include the following:

- Engineering, including owner approvals of drawings and specifications;

- Procurement, including equipment and material delivery durations and customs clearance activities;

- Construction, including the necessary detail to ascertain if all work is included and the critical path is realistic;

- Pre-Commissioning activities;

- Turnover activities in the sequence defined by the owner, if applicable;

- Start-Up and Commissioning activities; and

- Quality assurance and quality control activities.

Omission of a required portion of the original work scope within the project schedule could produce a project schedule with an overly optimistic duration for the work because the full scope is not reflected in the schedule. As a result, forecasted early and late dates, float values, completion dates, and the calculated critical path may be unreliable. In addition, if approved change order work is required to be incorporated into the project schedules, existing activity durations may need to be adjusted or fragnet activities may also need to be added to represent approved change order work in the schedule.

8.3 PERFORM SCHEDULE INTEGRITY CHECKS

Because the project schedule is a key management tool for measuring project progress over time, the project schedule should accurately reflect the impacts that have occurred during the execution of the work on specific work scopes, logic relationships, milestones, and completion work. However, it is not unusual for the project schedule to be deficient because it does not accurately depict all of the original scope of the project, activity logic is missing, contractual milestones are artificially constrained, and actual dates are incorrect.

When applying any of the available forensic schedule analysis methods such as the Time Impact Analysis (TIA) or As-Built But-For (Collapsed As-Built) Analysis, it is crucial that the underlying schedule data is accurate and free of obvious errors and deficiencies. If a multitude of errors and deficiencies in the underlying schedule data exist, then the supporting legitimacy of the schedule analysis may be invalid. Moreover, problems associated with the accuracy of project schedules may mask the true driving impacts that caused schedule delays, which may be the responsibility of the contractor and not the owner. Therefore, the basis for approving change orders and claims for time-related costs may be in question. It is important to evaluate the quality and reasonableness of project schedules and identify potential areas of deficiencies that affect schedule accuracy. Common items that can negatively affect the quality of a schedule include the following:

- Excessive number of open-end activities;

- Overly long activity durations;

- Activities with excessively high float values;

- Conflicting as-built dates;

- Overuse of negative lags;

- Excessively long negative lags;

- Excessively long positive lags;

- Overuse of constraints;

- Inconsistent use of schedule calculation modes;

- Budget resource loading conflicts; and

- Activities with incorrect status.

Correcting the contemporaneous project schedules for one or many of the above deficiencies may result in differing forecasted dates and activity float values. These corrections may cause the driving critical and near-critical path activities to change. Therefore, it is possible to identify owner-caused delays and impacts affecting what are thought to be driving critical path activities and then find, after correcting the schedule deficiencies, that the driving critical path activities are changed and were affected by delays and impacts that are the responsibility of the contractor. Without fixing these problems, the correct allocation of delay responsibility may be entirely wrong. In the following sections, examples of some of these deficiencies are examined.

8.3.1 Excessive Number of Open-End Activities

A fundamental schedule quality check is to determine if the schedule contains any open-end activities. Open-end activities are defined as activities that have no predecessor, no successor activity, or both. In theory, all activities should have at least one predecessor and one successor except for: (1) the project start activity (no predecessor activity); and (2) project completion activity (no successor activity). At a minimum, good scheduling practice should a have a very small number or no activities with open-ends. A large number of open-end activities will create erroneous float within the schedule as well as cause forecasted activities to be performed illogically (i.e., float from the data date to project finish). Correcting open-end activities will change float values that may affect the critical and near-critical activity forecast dates.

8.3.2 Large Number of High Float Activities

A project schedule with a large number of high float activities can be a problem. Float is defined as the amount of available time that the start or finish of an activity can be delayed without impacting a project’s overall finish date. Schedule paths with high float values typically arise due to artificially-constrained activities or other very long parallel critical paths. High float values can also result from a large number of activities with open-ends, which is a major issue. Schedules with a large number of high float activities should be examined and corrected for open-ends or missing logic ties that would better optimize the planned dates of activities with high float values.

8.3.3 Inconsistent Use of Schedule Calculation Modes

Retained logic is often the default calculation mode that contractors typically use for calculation of the schedule. Another type of scheduling calculation mode is progress override, which is less commonly used by contractors. Progress override is typically used to accelerate a schedule which allows out-of-sequence work activities to progress without delay and not wait until its logical predecessor is complete. Progress override is based on the premise that a contractor has all the necessary resources in terms of labor, equipment, and supervision that would allow for working in multiple areas concurrently.

However, in many cases, contractors will use progress override as a way to update a schedule without having to spend the time correcting out-of-sequence work activities. Even more disturbing is when contractors switch the schedule calculation modes for monthly updates from retained logic to progress override and then back to retained logic. If no plausible explanation by the contractor is provided, then the inconsistent switching of schedule calculation modes between updates is a deficiency. A consistent use of schedule calculation mode as represented by the baseline schedule should be used for the schedule updates.

8.3.4 Overuse of Constraints

Constraints are defined as restrictions on either the start or finish of an activity. Although constraints are often used in schedules, a large number of constraints should be avoided. Constraints artificially lock down a schedule and prevent a schedule to naturally “flow” during a forward and backward pass calculation to determine activity float values and the critical path of the project. In Long International’s experience, the total number of activities with constraints should be very low, and activities with constraints should have predecessor and successor logic.

Even then, the use of a constraint that causes a discontinuous critical path from the data date to project completion date should be avoided. Constraints are also too often used as a shortcut tactic by schedulers when they do not have enough time to properly update the schedule or account for out-of-sequence work. The overuse of constraints is also an indication of problems with open-ends or missing logic which may result in work activities with high float values.

8.4 COMPARISONS BETWEEN SCHEDULES

Forensic schedule analysis typically focuses on comparing as-planned schedules, periodic schedule updates, and as‑built schedules to identify delays to the critical and near-critical paths of the project. These delays may include either variances in the duration of an activity, variances in the start and finish dates, or variances in the planned and actual logic relationships and lag durations between predecessor or successor activities. Therefore, it is important to compare the schedule updates to baseline or rebaseline schedules or to previous schedule updates to identify changes made to the current schedule. Important schedule comparison checks include the following:

- Added and Deleted Activities;

- Activity Start and Finish Delays;

- Activity Duration Changes;

- Changes to the Critical/Near Critical Paths;

- Significant Changes to the Schedule Logic;

- Added Constraints;

- Changes in Schedule Calculation Modes;

- Changed Activity Coding;

- Added or Changed Resources; and

- Changed Activity Scope Definitions.

Frequently used forensic schedule analysis methods often employ some form of windows analysis approach (i.e., month-to-month comparisons) in evaluating the contemporaneous and cumulative impact of delays caused by each party on the contractual completion dates. Concurrent delays are also analyzed and evaluated to properly allocate the owner’s and contractor’s liability for delays. The bottom line is that significant schedule changes must be supported by reasonable explanations. If no reasonable explanations are provided and extensive changes between schedules are irreconcilable, the crucial element of proof using the project execution schedules to support a delay claim may be at risk.

9. CONCLUSION

Before starting a detailed schedule analysis in support of a change order or dispute, the first step is to perform forensic schedule quality assurance reviews of the baseline and contemporaneous project schedules used during project execution. The objective of a forensic delay analysis is to identify obvious deficiencies within the schedules and determine the level of effort needed to correct the problems to ensure that the schedule models used to measure, allocate, and prove schedule delay are reasonably accurate so that the analysis will withstand scrutiny. It is better to perform a forensic schedule quality assurance review early before expending significant time and cost analyzing a project schedule that may subsequently require extensive corrections.

About the Author

Ronald J. Rider, M.B.A., is a Senior Principal with Long International and has over 30 years of experience in construction project management and contract dispute resolution. Mr. Rider has performed CPM schedule development, project cost control, cost and labor hour variance modeling, impact identification and causation, change order pricing and resolution, retrospective schedule delay, time extension and acceleration analyses, concurrent delay assessments and damages quantification. Mr. Rider’s experience includes petrochemical, oil refinery, power, commercial, industrial, road/highway, transit, hospital/medical, airport and casino projects. He holds a B.S. degree in construction management from Colorado State University and an M.B.A. degree from the University of Colorado. Mr. Rider is based in the Denver, Colorado area and can be contacted at rrider@long-intl.com and (303) 346-5836.

1 For more discussions as to the reasons for claims, see Long International’s article “Why Claims Occur – The Red Flags.”

2 United States v. Spearin, 248 U.S. 132 (1918).

3 George A. Fuller Co. v. United States, 69 F. Supp. 409 (108 Ct. Cl. 1947)

4 For more detailed discussions regarding Long International’s considerations for schedule delay analysis, see Long International’s article “Schedule & Delay Analysis Methodologies.”

5 An Update Impact Analysis is also commonly used to add impacts to the schedule updates.

6 Long International has developed a standardized procedure and template for the specific elements needed for schedule quality assurance. See Long International’s article “Schedule Quality Assurance Procedures” for more detailed discussion.

7 Long International’s article “Contract Scheduling Provisions” provides a detailed discussion regarding contract provisions and case law affecting the preparation and updating of schedules, and the preparation of and defense against change orders and delay and disruption claims.

Copyright © Long International, Inc.

ADDITIONAL RESOURCES

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE