September 26, 2023

Missing Schedule Activities Related to Engineering Drawing Revisions

A project’s engineering, procurement, and construction schedule should encompass the full scope of work. As the project evolves and scope is revised or added through changes, contractors typically modify or add schedule activities to capture the revised work. However, in my experience, one area in which the schedule often fails to reflect reality is engineering drawing revisions. While omitting drawing revisions may not impact the project team’s planning during the project, the gap in the schedule can significantly impact an expert’s delay analyses in a dispute.

There are multiple reasons why drawing revisions are not included in the schedule updates, but often it is due to the following: (1) the scheduler updates baseline activities only but does not add activities such as drawing revisions due to the work and time required; (2) drawing revisions or multiple drawing reviews are not always captured through change orders, and thus are not added to the schedule updates; and (3) the work is considered non-critical and/or unlikely to impact follow-on work. Often, drawing revisions past Rev. 0, Issue for Construction, are relatively minor and do not substantively affect follow-on procurement and construction work. However, I have been involved on mega-projects, with sophisticated contractors creating detailed schedules, in which the schedules failed to reflect thousands of drawing revisions issued over the course of years. In a dispute, the potential impact of such drawing revisions must be considered in a delay analysis and a disruption analysis, even when they are omitted from the schedule updates.

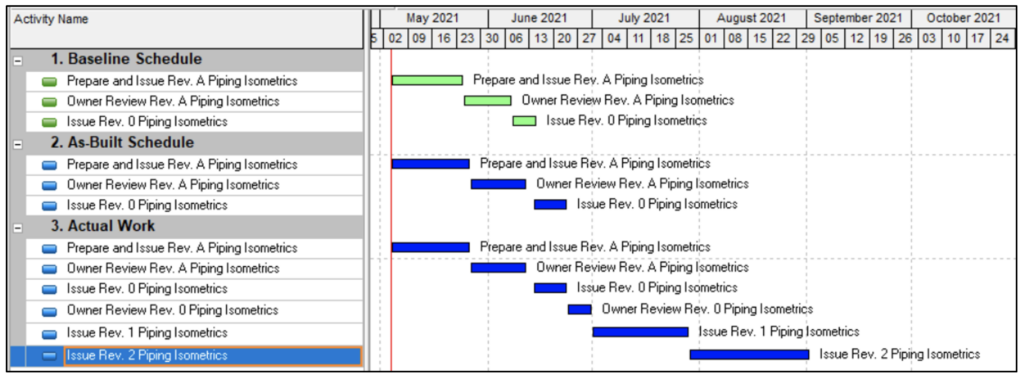

The bar chart below shows a typical example. The EPC contractor included three activities in its baseline schedule to reflect the work involved in issuing piping isometric drawings for a specific plant area and system, including a period for a single owner review. In the schedule updates and the as-built schedule, the contractor accurately updated those three activities, with the final activity shown completed when the final Rev. 0 isometric was issued. However, as shown under “3. Actual Work,” the owner then reviewed the Rev. 0 isometrics and the contractor issued Rev. 1 and Rev. 2 isometrics over a two-month period, none of which were included in the schedule updates or the as-built schedule (presently shown in bar chart format only for comparison purposes).

For a process plant project, the critical path often runs through the issuance of piping isometric drawings, followed by the fabrication of pipe spools and then the installation of pipe spools. A scheduling expert preparing or evaluating a delay claim may determine that the issuance of Rev. 0 piping isometrics activities in the schedule above were only near-critical, but the expert has only used the Rev. 0 issuance dates in the as-built schedule and has not considered the further Rev. 1 and Rev. 2 drawing issuances. The expert’s analysis could rightly be questioned regarding the omission of actual work and accuracy of the conclusions. For example, would this area/system be on the critical path if later issuances of drawing revisions were considered in the delay analysis? How many pipe spools could be fabricated based on the Rev. 0 isometrics versus the Rev. 1 and Rev. 2 isometrics? Was the start of pipe installation work delayed because of piping isometric drawing revisions? Was the installation disrupted as a result of piping isometric drawing revisions?

This example highlights the fact that a scheduling expert must ensure, amongst many other baseline, update, and as-built schedule verification steps, that the schedules include the project’s entire scope of work, including engineering drawing revisions.

ADDITIONAL RESOURCES

Blog

Discover industry insights on construction disputes and claims, project management, risk analysis, and more.

MORE

Articles

Articles by our engineering and construction claims experts cover topics ranging from acceleration to why claims occur.

MORE

Publications

We are committed to sharing industry knowledge through publication of our books and presentations.

MORE

RECOMMENDED READS

Key Elements for Successful Schedule Management

The purpose of this article is to help put into perspective the key considerations that should be given to the scheduling program on projects.

READ

Long International’s Schedule and Delay Analysis Methodologies

We explain our detailed schedule analysis methodology using a construction delay claim on a hypothetical wastewater treatment plant project.

READ

Choosing the Most Appropriate Schedule Analysis Method

This article presents an overview of each of the nine schedule analysis methodologies, the strengths and limitations of each method, and more.

READ